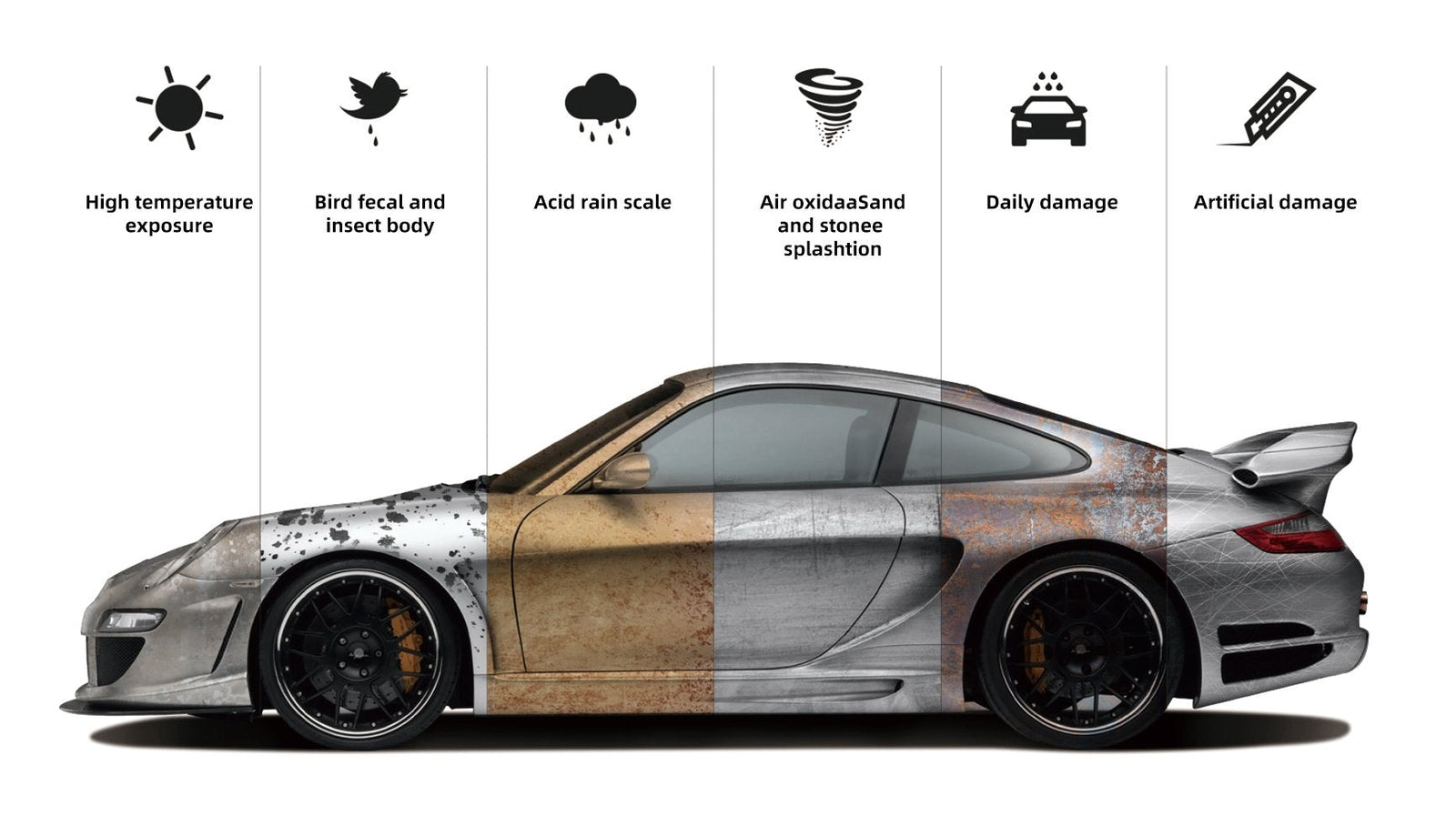

Protect Original Factory Paint

A vinyl wrap protects your vehicle's paint from scratches, minor abrasions, and fading due to UV exposure.

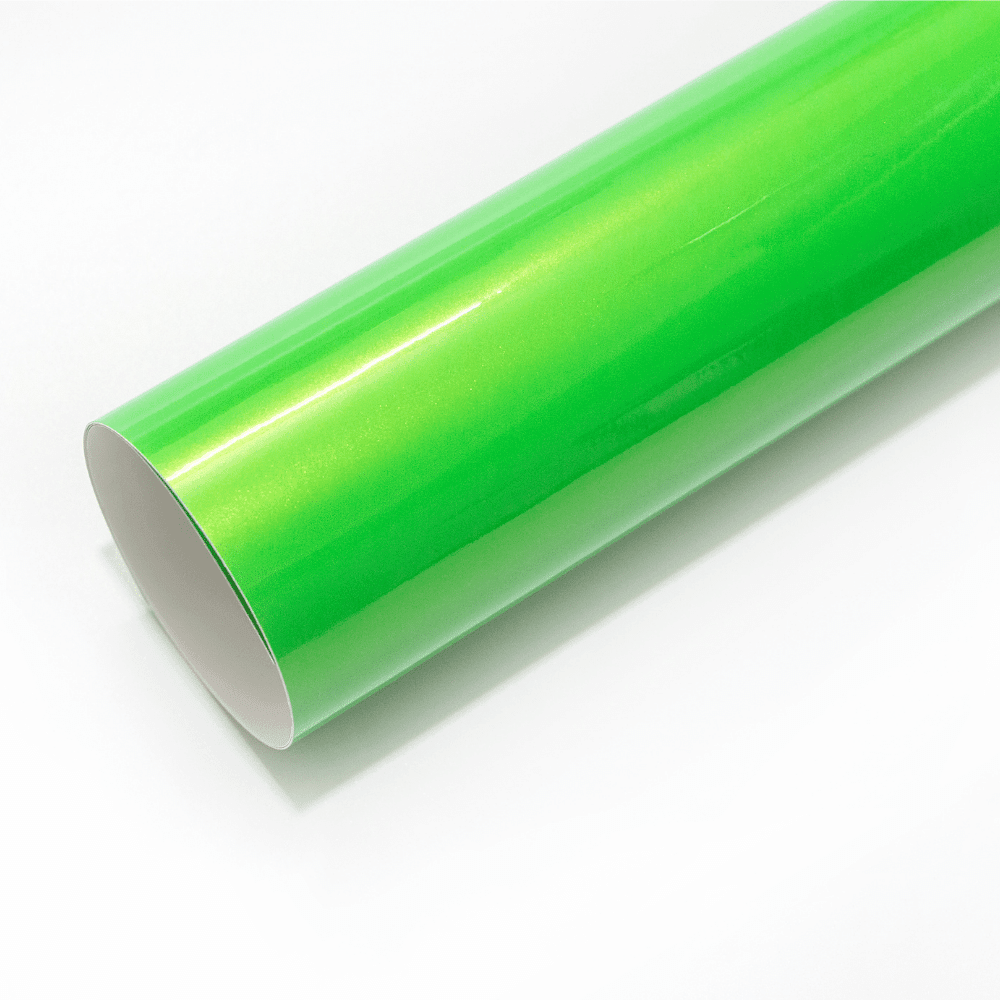

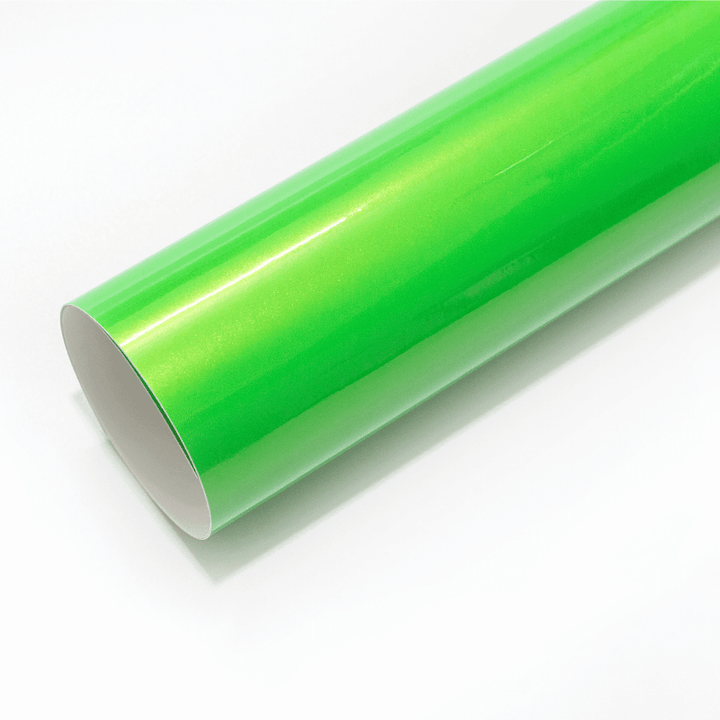

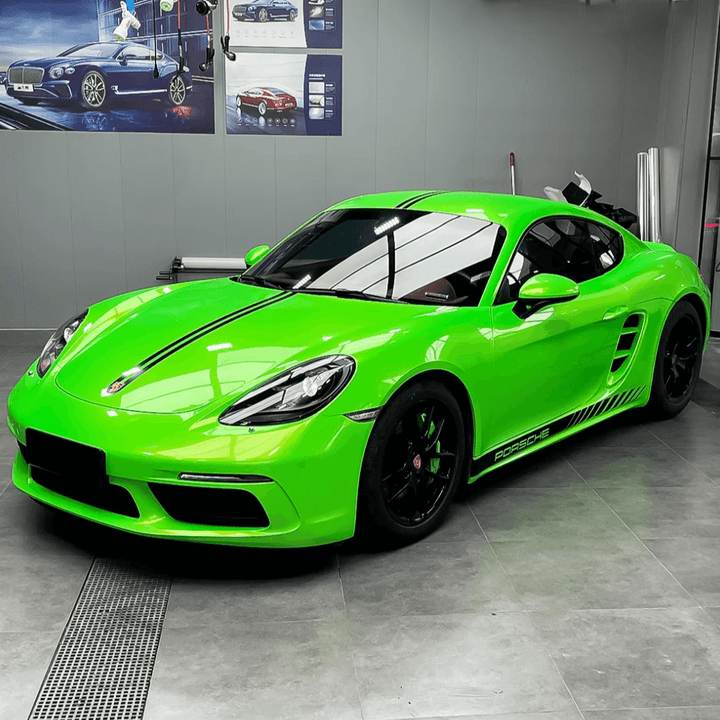

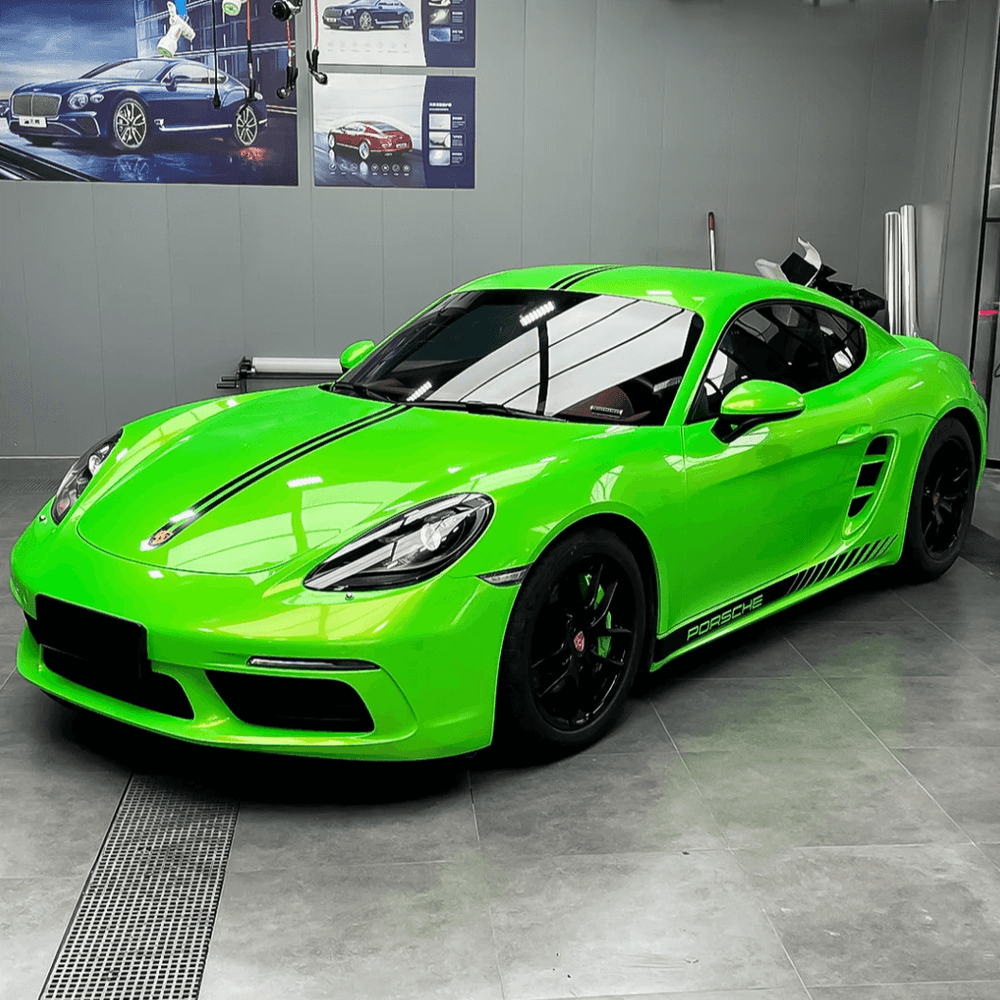

Neon Green Pearlescent Vinyl Wrap is a color-enhancing film that combines a vivid neon green base with fine pearl particles, creating a bright yet controlled glow that reacts smoothly to light and viewing angle. Unlike flat neon colors that can appear harsh, or metallic finishes that rely on sharp sparkle, the pearlescent effect softens the intensity while preserving the unmistakable energy of neon green.

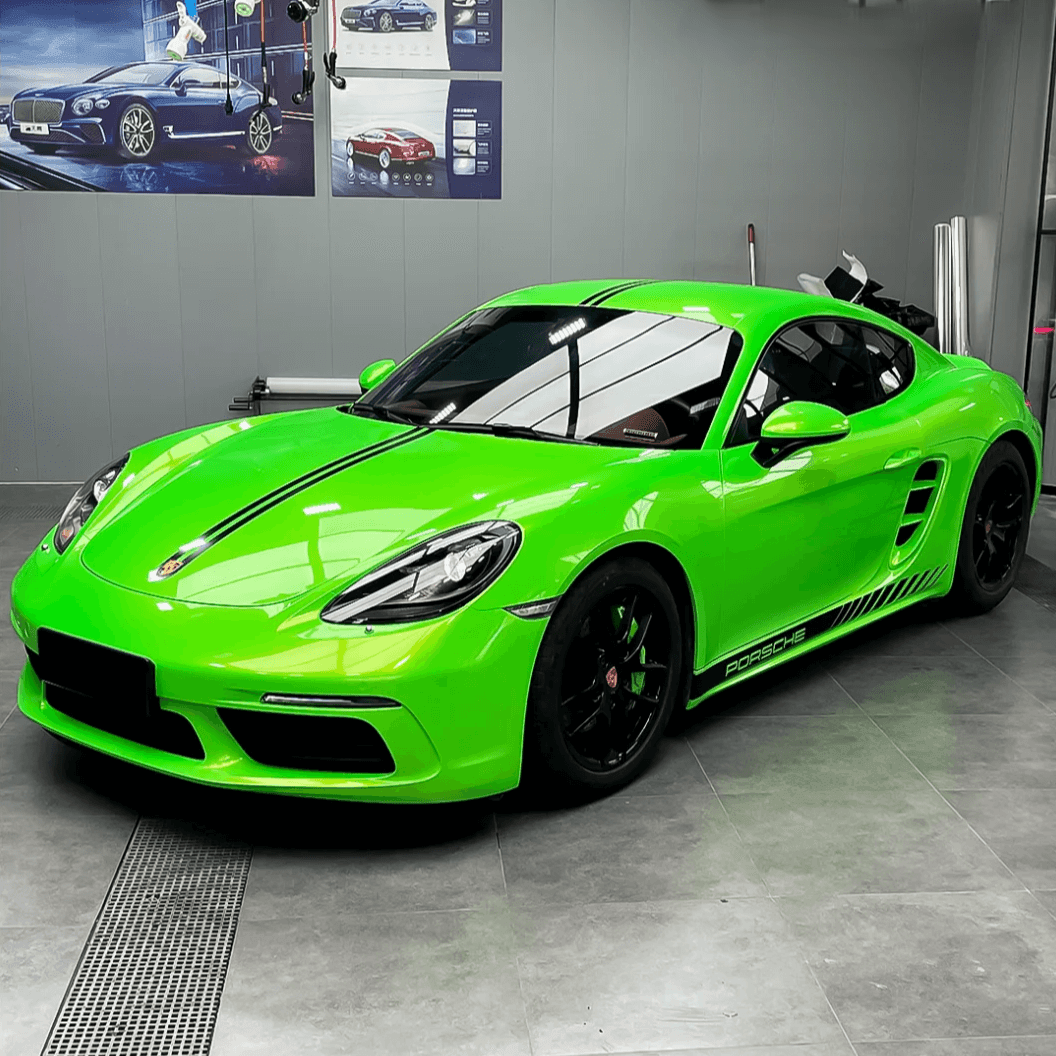

This wrap is designed for drivers who want their vehicle to stand out clearly without looking raw or unfinished. In bright daylight, the color appears vibrant and electric, with a clean surface that reflects light evenly. As lighting conditions change, the pearl layer adds subtle movement across the surface, keeping the color lively without dramatic or distracting shifts. The result is a bold but balanced finish suitable for full wraps or focused accent applications.

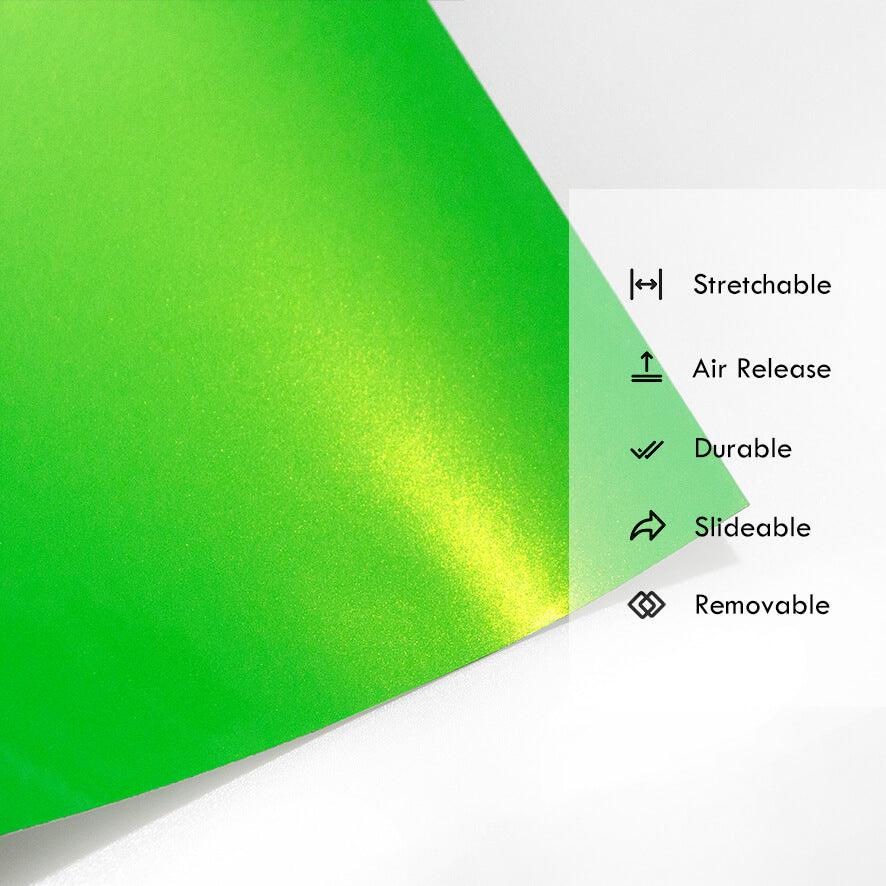

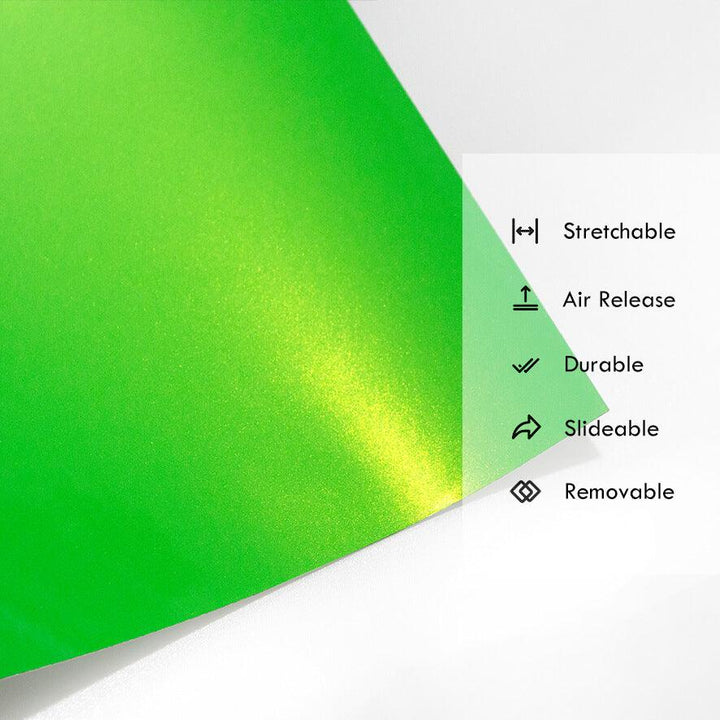

Built with advanced air-release adhesive technology, our Neon Green Pearlescent Vinyl Wrap allows for smooth, bubble-free installation and easy repositioning. It offers a paint-safe and fully reversible way to transform your vehicle’s appearance without permanent modification.

What Is Neon Green Pearlescent Vinyl Wrap

Pearlescent vinyl wrap uses microscopic pearl pigments embedded within the film to reflect and diffuse light softly. Unlike metallic vinyl, which depends on aluminum flakes for sharp reflections, pearlescent vinyl creates a smoother glow with controlled highlights.

In a neon green pearlescent finish, this technology plays an important role. Neon green on its own can feel intense or overly flat. The pearlescent layer adds dimension by breaking up the surface visually, introducing gentle highlights that follow body lines and contours. This keeps the color expressive while making it easier to view from different distances and angles.

Neon green pearlescent vinyl sits between solid neon colors and metallic wraps, offering a refined alternative that feels modern, premium, and visually stable.

Key Features and Benefits

-

Bright neon green base enhanced with fine pearl particles

-

Energetic color presence with a smoother, refined glow

-

Soft light diffusion without harsh metallic sparkle

-

Eye-catching appearance suitable for performance and show builds

-

Scratch-resistant and UV-protected surface layer

-

High-grade polymeric vinyl for durability and weather resistance

-

Pressure-sensitive adhesive with air release channels

-

Easy repositioning during installation

-

Removable adhesive that protects factory paint when removed correctly

Technical Specifications

|

Feature |

Specification |

Benefit |

|

Finish |

Pearlescent |

Soft glow with controlled light reflection |

|

Color |

Neon Green |

High-visibility, energetic tone |

|

Material |

High-grade Polymeric Vinyl |

UV resistant, waterproof, durable |

|

Adhesive |

Pressure-sensitive with Air Release |

Bubble-free installation |

|

Heat Stretch |

Up to 30% stretchability |

Conforms to curves and complex shapes |

|

Durability |

5 to 7 years indoor, 3 to 5 years outdoor |

Long-lasting color stability |

Neon Green Pearlescent vs Other Green Finishes

Neon Green Pearlescent vs Solid Neon Green Wrap

Solid neon green vinyl delivers maximum brightness but often looks flat across large panels. Without variation, the surface can feel overly sharp or unfinished.

Neon green pearlescent vinyl introduces subtle highlights that follow the vehicle’s shape, adding dimension while keeping the color bold. The result is a cleaner, more polished look that still commands attention.

Neon Green Pearlescent vs Metallic Green Wrap

Metallic green vinyl uses reflective flakes that create sparkle and strong contrast. While visually striking, it can appear busy or overly reflective.

Pearlescent neon green offers a smoother surface with controlled light response, making it easier to pair with black trim, carbon fiber accents, or matte details.

Where Neon Green Pearlescent Vinyl Works Best

Neon green pearlescent vinyl wrap is well suited for applications where visibility and personality matter.

Exterior applications include:

-

Full vehicle wraps for bold, high-impact builds

-

Hoods, roofs, doors, and quarter panels

-

Mirrors, spoilers, and accent sections

Interior and custom uses include:

-

Dashboards and interior trim accents

-

Motorcycles, helmets, and performance equipment

-

Bicycles, scooters, and custom projects

-

Furniture panels and display elements

Because the pearlescent effect responds smoothly to curves and edges, it performs especially well on sculpted body panels and aerodynamic designs.

Why Choose Neon Green Pearlescent Wrap from Yeswrap

Yeswrap’s Neon Green Pearlescent Vinyl Wrap is manufactured using high-quality polymeric vinyl developed for both professional installers and experienced DIY users.

The pressure-sensitive adhesive includes integrated air release channels that help eliminate bubbles and wrinkles during application. The film can be lifted and repositioned, allowing precise alignment before final adhesion.

With up to 30% stretchability, the vinyl conforms easily to curved surfaces, recessed areas, and complex shapes without distorting the pearlescent finish or dulling the neon color.

High-Quality Vinyl with a Cost-Effective Price

Achieving a high-impact neon finish does not require an expensive custom paint job. Our Neon Green Pearlescent Vinyl Wrap delivers a premium look at a fraction of the cost.

Material cost for a full sedan wrap typically runs around $630. Accent applications or partial coverage often stay under $300 in material.

Professional installation, including vinyl, generally ranges from $2,500 to $5,000 depending on vehicle size and complexity.

Because the wrap is removable, it allows you to experiment with bold color choices while protecting the original paint and resale value.

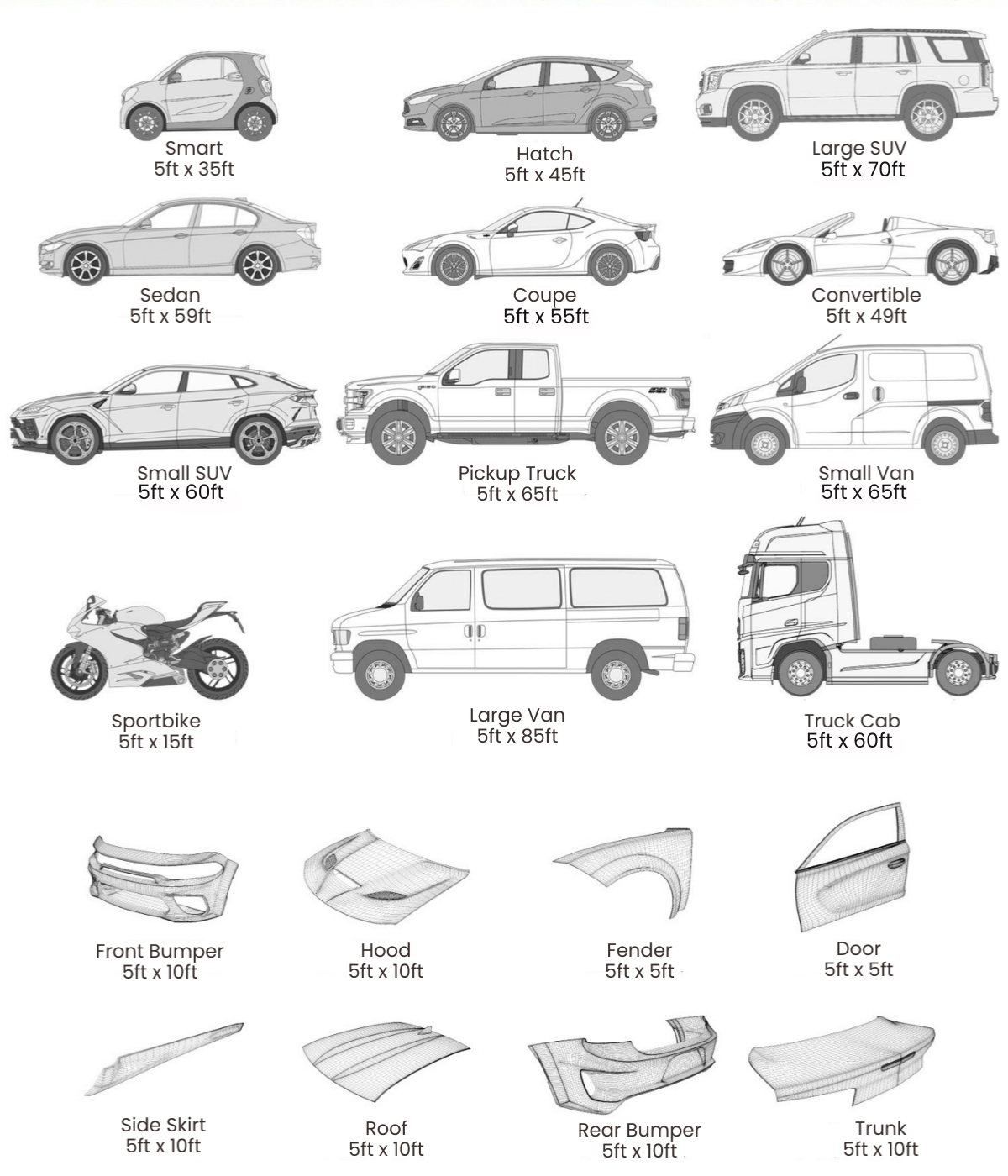

Multiple Size Options Available

Our Neon Green Pearlescent Vinyl Film is available in multiple size options to match different project needs. From small sheets for trim pieces to full 5 ft by 59 ft rolls for complete vehicle wraps, you can select the size that best fits your application and reduces material waste.

Installation and Maintenance Tips

For best results, proper installation and care are essential.

-

Clean the surface thoroughly using isopropyl alcohol to remove dust, wax, and oils.

-

Measure and cut the vinyl, leaving extra material for trimming and adjustments.

-

Apply the film from the center outward using a felt-edge squeegee.

-

Use moderate heat to soften the vinyl when working around curves and edges.

-

Apply post-heat to secure edges and activate adhesive memory.

For maintenance, hand washing with mild soap is recommended. Avoid abrasive cleaners or automatic car washes with stiff brushes to preserve the pearlescent surface and neon color clarity.

Frequently Asked Questions

Is neon green pearlescent vinyl too bright for daily driving

The color is bold, but the pearlescent finish softens the surface, making it more refined and easier to live with than flat neon finishes.

Does neon green pearlescent look different at night

In low light, the color remains visible and clean, with the pearl effect becoming more subtle rather than dramatic.

Will pearlescent vinyl fade faster due to its brightness

No. The vinyl is UV protected and designed to maintain color stability under normal outdoor conditions.

Is neon green pearlescent vinyl harder to install

Installation is similar to other premium vinyl wraps and does not require special techniques beyond standard vinyl installation practices.

Bold Neon Energy with a Refined Finish

If you are looking for a green wrap that delivers strong visual impact without harsh shine or excessive sparkle, Yeswrap’s Neon Green Pearlescent Vinyl Wrap offers a balanced solution. It combines neon-level visibility with a smooth, pearlescent surface that feels polished and intentional.

All orders include free fast shipping. Your vinyl wrap will be delivered directly to your doorstep within 7 to 12 days. Choose your preferred size and transform your vehicle with the energetic yet refined character of neon green pearlescent vinyl.

Specifications

|

Classification |

Spec |

|

|

Type of film |

High-grade polymeric calendered film |

|

|

Adhesive |

Low-Tack pressure-sensitive acrylic adhesive |

|

|

Top protective cap |

Plastic film |

|

|

Release liner |

PET/Paper |

|

|

Thickness(μm) |

Top protective cap |

36±2% |

|

Vinyl film |

120±2% |

|

|

Adhesive |

30±2% |

|

|

Release liner |

130±2%(PET); 160±2%(Paper) |

|

|

Indoor expected durability |

5 years when following rules of application and use |

|

|

Outdoor expected durability |

3 years when following rules of application and use |

|

|

Storing period |

2 years if stored in +10°С to +20°С, relative humidity 50%, in original package, away from direct sunlight, in a clean and dry place. |

|

Vinyl Film Properties

|

Classification |

Test Method |

Standard |

Results |

|||

|

Release force N/25mm |

Temperature 25℃ and Humidity 50% |

0.20-0.40 |

0.35 |

|||

|

Initial tack g/25mm |

26℃ and 64% GB31125-2014 |

800-1500 |

1015 |

|||

|

Peel Strength N/25mm |

25℃ and 42% GB/T2792-1998 |

≥4.9 |

8.1 |

|||

|

Adhesion strength |

25℃ and 50% GB/T4851-1998 |

≥60 |

110 |

|||

|

Aging |

65℃; 7 days |

High-temperature release without adhesive residue |

No adhesive residue with heat |

|||

|

-65℃; 10 days |

Low-temperature release without adhesive residue |

No adhesive residue without heat |

||||

Recommended Application Tools:

- Squeegee

- Utility knife

- Masking tape

- Heat gun

- Magnets

- Gloves

Application Guidelines:

Follow standard procedures for applying calendered films. Avoid overstretching or overheating the material. Post-heating is essential to ensure proper adhesion and finish.

Post-Heating Guidelines:

- Flat Surfaces: Heat to 110°C for optimal adhesion.

- Curves and Overlaps: Increase temperature to 130°C to ensure proper conformity and bonding.

Aftercare Instructions:

- Use only pH-neutral cleaning products for maintenance.

- Avoid wax, solvents, or harsh chemicals to preserve the material's integrity.

Wrap Size Chart

Need Sample?

If you are worried about whether the color is what you want, order a sample first!

How Vinyl Wraps Made?

Want to know how vinyl is made? We use the most advanced technology and the highest quality materials to produce high-grade vinyl wraps!

DIY Wrapping Tutotial

Want to do it yourself? Follow our step by step tutorial to get your hands dirty.

FAQs

No, the vinyl films we sell have a non-permanent adhesive, making them easily removable. Typically, a vinyl wrap lasts 3-7 years, depending on the material used, driving conditions, sun exposure, and storage. When it’s time to remove the wrap, it can be done without damaging the paint, returning your car to its original color and condition. While some glue residue may be left behind, it can be easily removed with rubbing alcohol or by rubbing it off with your finger.

It's recommended to remove the vinyl wrap after 3-5 years, as leaving it on longer could potentially damage the clear coat and even the paint. However, issues may arise if the car was repainted, resprayed, or if the paint was already in poor condition at the time of installation. In such cases, there is no guarantee that the vinyl wrap won’t cause damage or peel off paint during removal, and this applies to all brands of vinyl wraps.

Our vinyl films are versatile and can adhere to a variety of surfaces, both vehicle's exterior and interior, as well as marine and architectural applications. The vinyl will stick confidently to any painted surface on a vehicle and most smooth, non-porous materials like bare metal and plastic. However, it may not adhere well to certain interior surfaces, such as rubber (soft or hard), leather, and non-smooth plastics that are ribbed or textured.

Vinyl films typically last between 3 to 7 years, depending on the environment. In sunnier climates, such as the Southern United States (California, Florida, Texas, etc.), the lifespan of the vinyl may be reduced by 20-30% due to stronger sunlight exposure. The closer you are to the equator, the faster the vinyl may fade or crack. This is especially true for colors with a high content of red pigment, such as red, purple, yellow, pink, and copper, which tend to fade more quickly.

The quality of the installation also plays a crucial role in the durability of the wrap. A properly installed wrap will maintain its look and feel longer and is less likely to fail by curling or peeling back.

To calculate the amount of vinyl needed to wrap your vehicle, you can use the following simple formula:

- Determine Vehicle Length: Measure the length of your vehicle in inches.

- Multiply by 3: Multiply the length by 3 to cover both sides and the top.

- Add Extra Vinyl: Add 5 to 15 feet for bumpers, mistakes, and complex areas.

- Round Up: Always round up to the nearest roll size.

Example Calculation:

For a 2016 Ford Mustang, which is 188 inches long:

- Length Calculation: (188" x 3) + 10 ft = 47 ft + 10 ft = 57 ft.

- Closest Roll Size: You would need to purchase a 5ft x 60ft roll.

♦ Small size cars can be fully wrapped with 50 to 55 feet / 15 to 16.8 meters of vinyl.

example of vehicle sizes:

Audi A3 & A4, BMW 2 & 3 series, Mitsubishi Lancer, Subaru Impreza, VW Golf & Beetle & Jetta, Hyundai Elantra, Nissan Sentra, Mercedes C-class

♦ Midsize cars can be fully wrapped with 60 to 65 feet / 18.3 to 19.8 meters of vinyl.

examples of vehicles:

Chevrolet Camaro, Corvette, Ford Mustang, Ford Fusion, Toyota Camry, Honda Accord, VW Passat & CC, Nissan Maxima/Altima, Audi A5 & A6, BMW 5 series, Mercedes E-class, Hyundai Sonata,

♦ Full-size cars; small SUVs, small trucks & small vans need 60 to 70 feet / 18.3 to 21.3 meters of vinyl

examples of vehicle sizes:

Audi A7 & A8, Ford Taurus, Chevrolet Impala, BMW 7 series, Mercedes limousines & S class, Hummer 3, 4Runner, FJ Cruiser

♦ Full-size SUVs, trucks & minivans 70 to 85 feet / 21.3 to 25.9 meters of vinyl

examples of vehicle sizes:

Suburban, Escalade, Land Rover, Cayenne, Hummer, H2, Voyager, Town & Country, Sienna, Routan

For more information, please browse our article to calculate the amount of vinyl you need.

Vinyl wraps are not intended to match the original color of your vehicle. They are designed to change or replace the vehicle's color with unique, non-OEM options that manufacturers create. Vinyl wrap films are made by mixing pre-mixed dye with PVC-based material, which is then produced into large rolls of vinyl.

Due to the nature of the manufacturing process, even wraps from the same color batch can have slight shade differences. This variability means that a perfect color match to your vehicle’s original paint is not possible with vinyl wraps. Their primary purpose is to provide a distinct and customized look rather than replicate the existing color.