How Are Yeswrap Vinyl Wraps Made?

Vinyl wraps are a highly effective solution for various uses, particularly in vehicle wrapping, where they provide durability, cost-efficiency, and versatility. When applied to cars, trucks, buses, or trailers, vinyl wraps offer a practical and economical way to customize appearance and protect vehicle paint. In the advertising world, calendered vinyl is widely used for outdoor signs, window displays, and temporary promotional materials due to its durability and ease of installation.

In this article, we invite you to explore the production process of Yeswrap calendered vinyl wraps. By understanding how our vinyl wraps are made, you’ll gain valuable insights into their key advantages, such as affordability and long-lasting performance in outdoor environments. This knowledge will help you choose the right type of vinyl for your specific needs, ensuring that you get the most out of its lifespan and effectiveness.

Understanding Calendared Vinyl Wraps

What is Calendered Vinyl Wrap?

Calendered vinyl wrap is a type of vinyl film that is created through a process called calendering, where heated PVC (polyvinyl chloride) material is passed through a series of rollers to produce a flat, uniform sheet. This manufacturing method results in a thicker, more durable vinyl film compared to cast vinyl, which is made by pouring liquid PVC into molds. Because of its production process, calendered vinyl is less flexible and conformable but highly robust, making it a preferred choice for applications on flat or slightly curved surfaces.

Calendered vinyl thickness typically ranges from 3 to 6 mils (thousandths of an inch). This added thickness provides more rigidity, making it less suitable for wrapping complex, irregular surfaces or tight curves, but excellent for larger, flat areas like the sides of sedans, trucks, buses, and walls. The increased durability of calendered vinyl makes it resistant to abrasions, weathering, and outdoor elements, allowing it to maintain its appearance for extended periods under various environmental conditions.

Key Characteristics of Calendared Vinyl Wraps:

-

Material Composition: Made primarily from polyvinyl chloride (PVC), calendared vinyl wraps are processed through a method called calendaring, where the material is heated and pressed between rollers to achieve the desired thickness and flexibility.

-

Variety of Finishes: Available in numerous finishes such as gloss, matte, satin, and textured options like carbon fiber or brushed metal.

-

Thickness Range: Typically ranges from 3 to 6 mils, providing a balance between durability and flexibility.

Benefits of Using Calendared Vinyl Wraps

Calendared vinyl wraps offer numerous advantages that make them a popular choice among car enthusiasts and businesses alike:

-

Durability: High-quality calendared vinyl is designed to withstand environmental factors such as UV rays, moisture, and temperature fluctuations. Studies show that properly maintained wraps can last between 3 to 5 years, making them a reliable option for vehicle customization.

-

Cost-Effectiveness: Compared to traditional paint jobs, vinyl wraps are often more affordable while still providing a high-quality finish. The average cost of a full vehicle wrap ranges from $3,500 to $6,500, which can be significantly less than a full repaint.

-

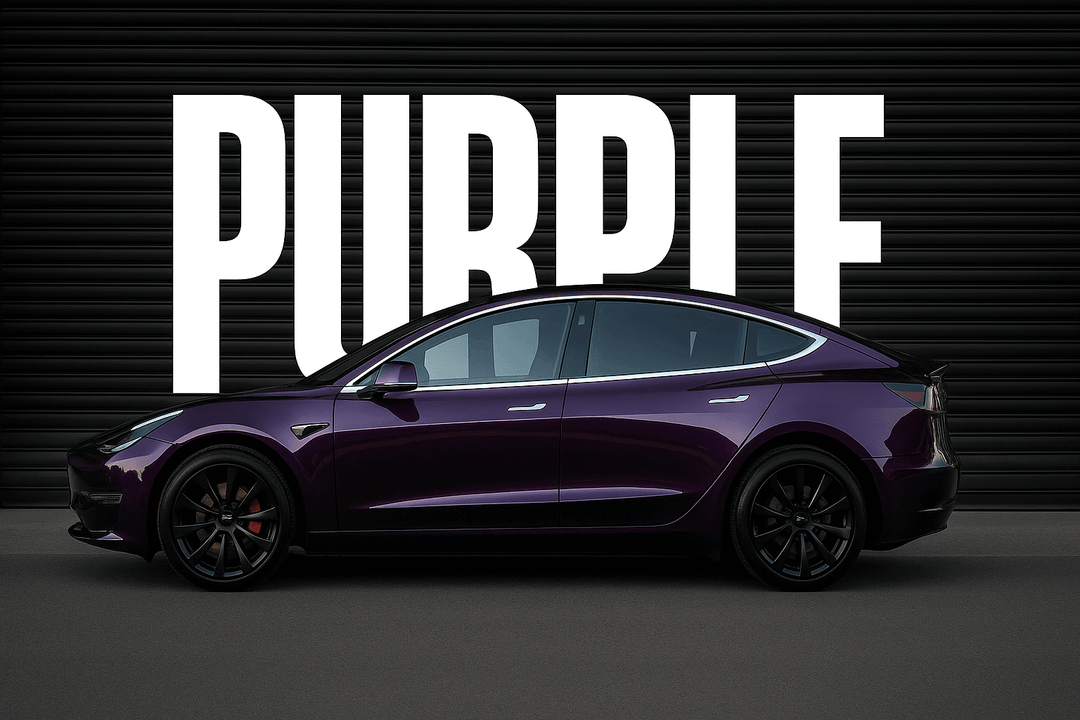

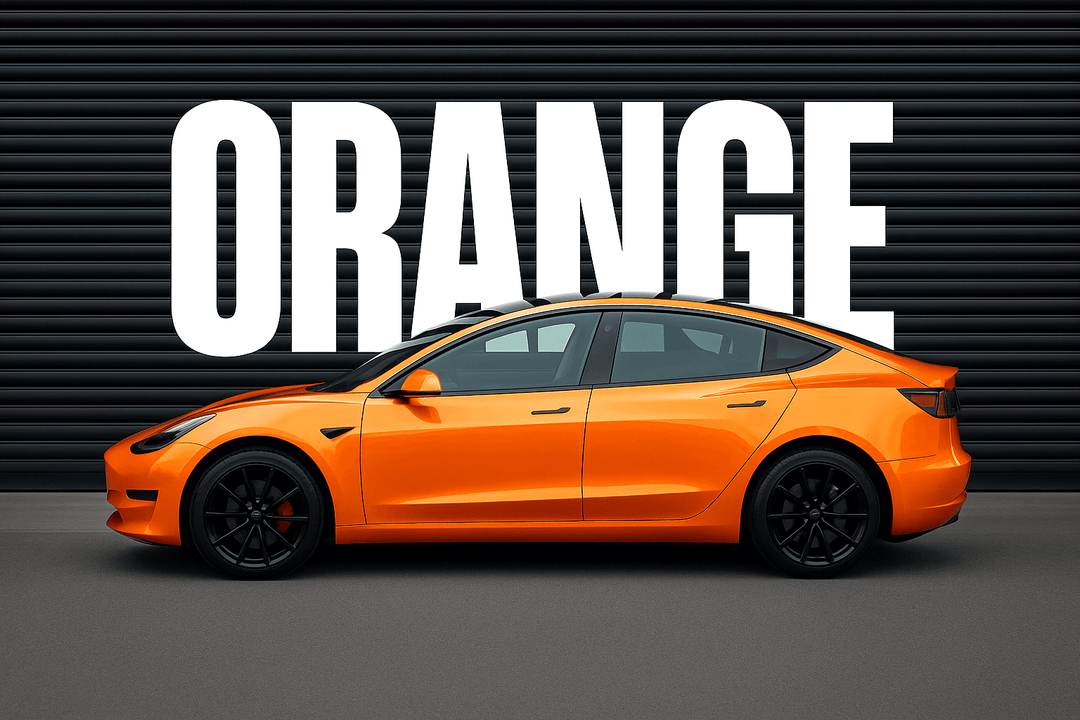

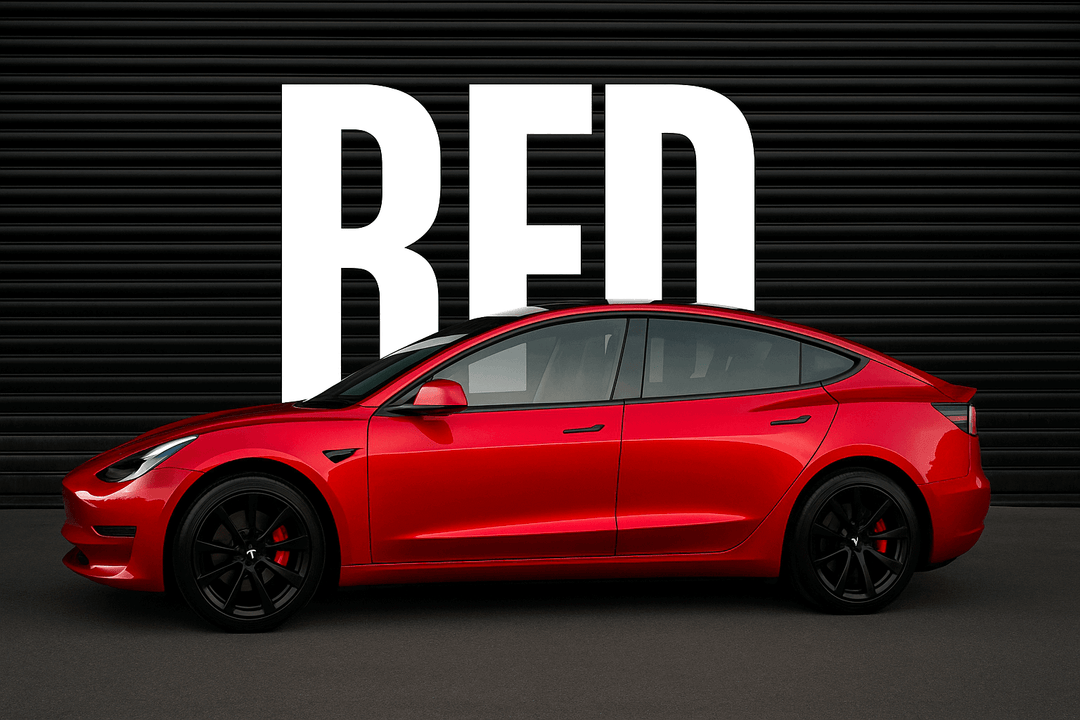

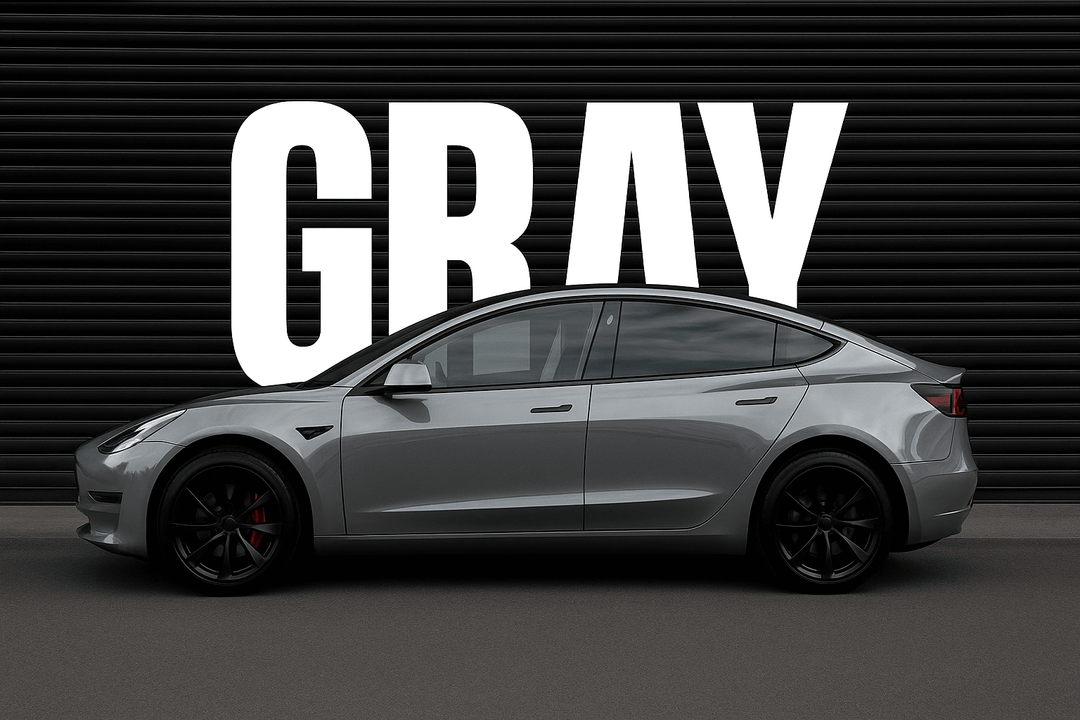

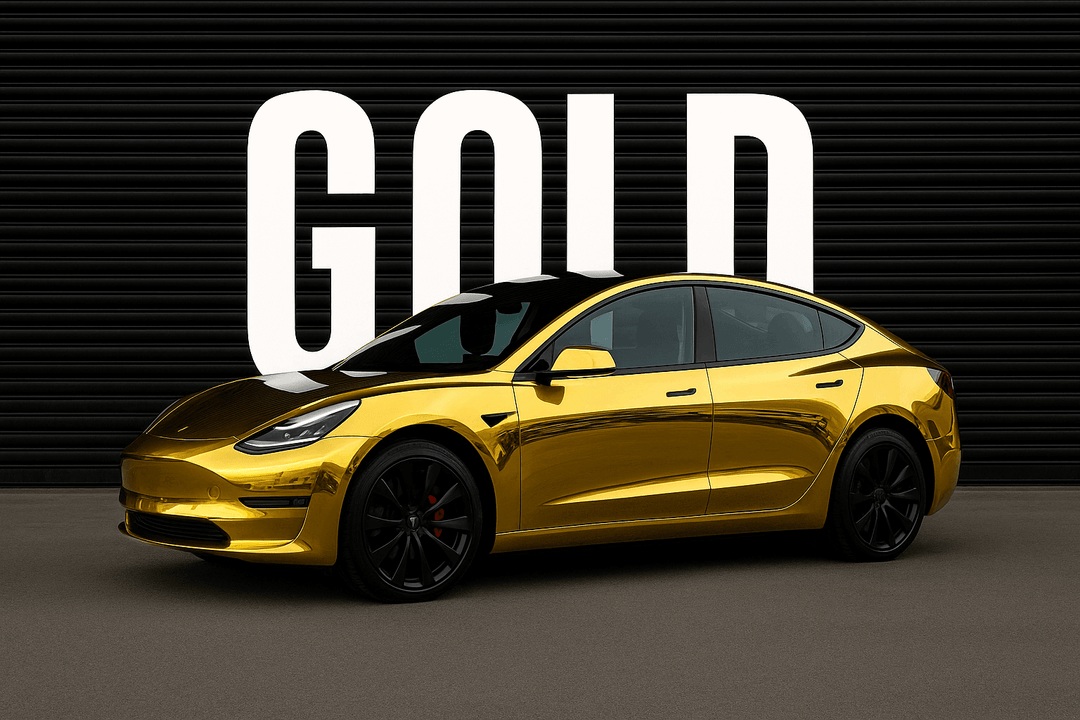

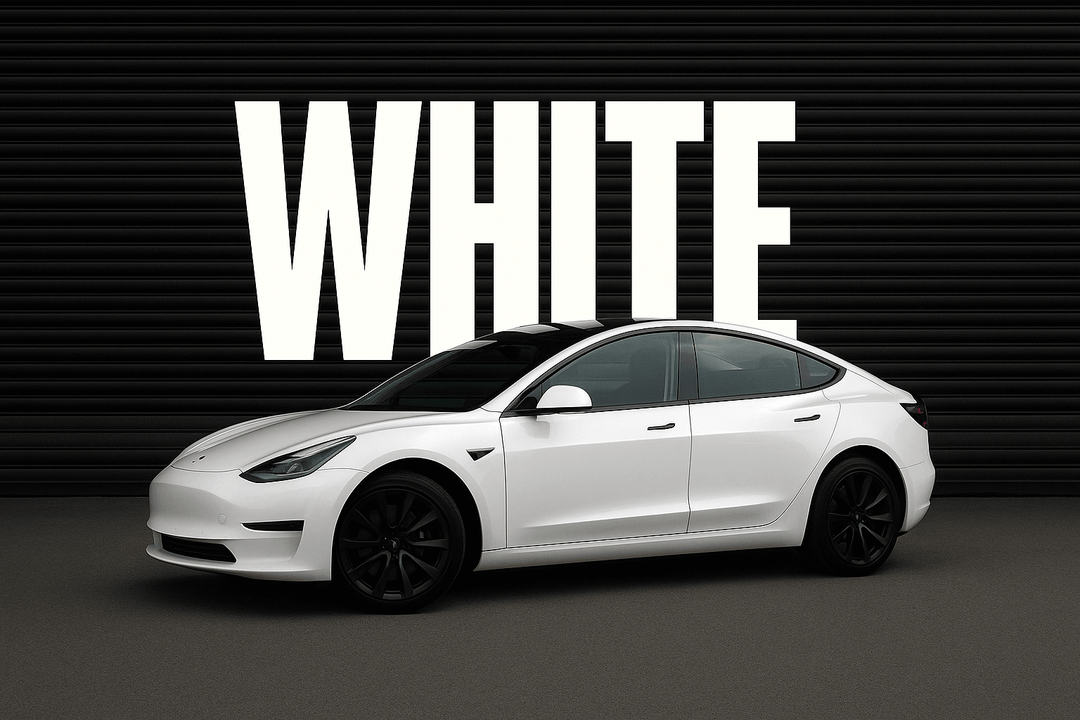

Customization Options: With a wide array of colors, textures, and finishes available, vehicle owners can express their personal style or brand identity. For example, YesWrap offers collections ranging from Gloss Vinyl Wraps to Chameleon Vinyl Wraps that cater to diverse aesthetic preferences.

-

Reversibility: Unlike paint, which can be permanent, vinyl wraps can be removed without damaging the underlying surface. This allows for flexibility in design; if trends change or if a vehicle owner wishes to revert to the original color, they can do so easily.

The Intricate Process of Making Calendared Vinyl Wraps

The production of calendared vinyl wraps involves several meticulous steps that combine advanced technology with skilled craftsmanship. Below is a detailed overview of each stage in the manufacturing process.

1. Material Selection

The journey begins with the careful selection of high-quality polymers. These polymers serve as the base for the vinyl material, ensuring durability, flexibility, and resistance to environmental elements. Key materials include:

| Material Type | Description |

|---|---|

| PVC (Polyvinyl Chloride) | The primary component used for its durability and versatility. |

| Additives | UV stabilizers and plasticizers enhance performance and longevity. |

| Recycled Materials | Increasingly, manufacturers are incorporating recycled PVC to promote sustainability. |

- Explore our collection of Eco-Friendly Vinyl Wraps to see sustainable options available for your projects.

2. The Calendaring Process

The heart of calendared vinyl wrap production lies in the calendaring process itself. This involves passing the vinyl material through a series of heated rollers that flatten and shape it into sheets.

-

Thickness Control: The thickness can be adjusted based on application needs—typically ranging from 3 to 6 mils.

-

Texture Options: Different rollers can create various textures (e.g., glossy, matte, or textured finishes).

3. Color Infusion

Calendared vinyl wraps come alive with vibrant colors during the manufacturing process. Pigments and dyes are skillfully blended into the vinyl material. This infusion ensures that:

-

Color Consistency: The color remains uniform throughout the wrap.

-

Fade Resistance: High-quality pigments prevent fading from UV exposure over time.

-

Check out our Gloss Vinyl Wraps for vibrant color options that stand out!

4. Design Precision

The production process integrates cutting-edge technology to ensure precision in design. Intricate patterns, graphics, and textures are etched onto the vinyl material using advanced printing techniques such as digital printing or screen printing:

| Printing Technique | Advantages |

|---|---|

| Digital Printing | Allows for complex designs and full-color graphics; suitable for short runs. |

| Screen Printing | Ideal for large quantities; provides vibrant colors with excellent opacity. |

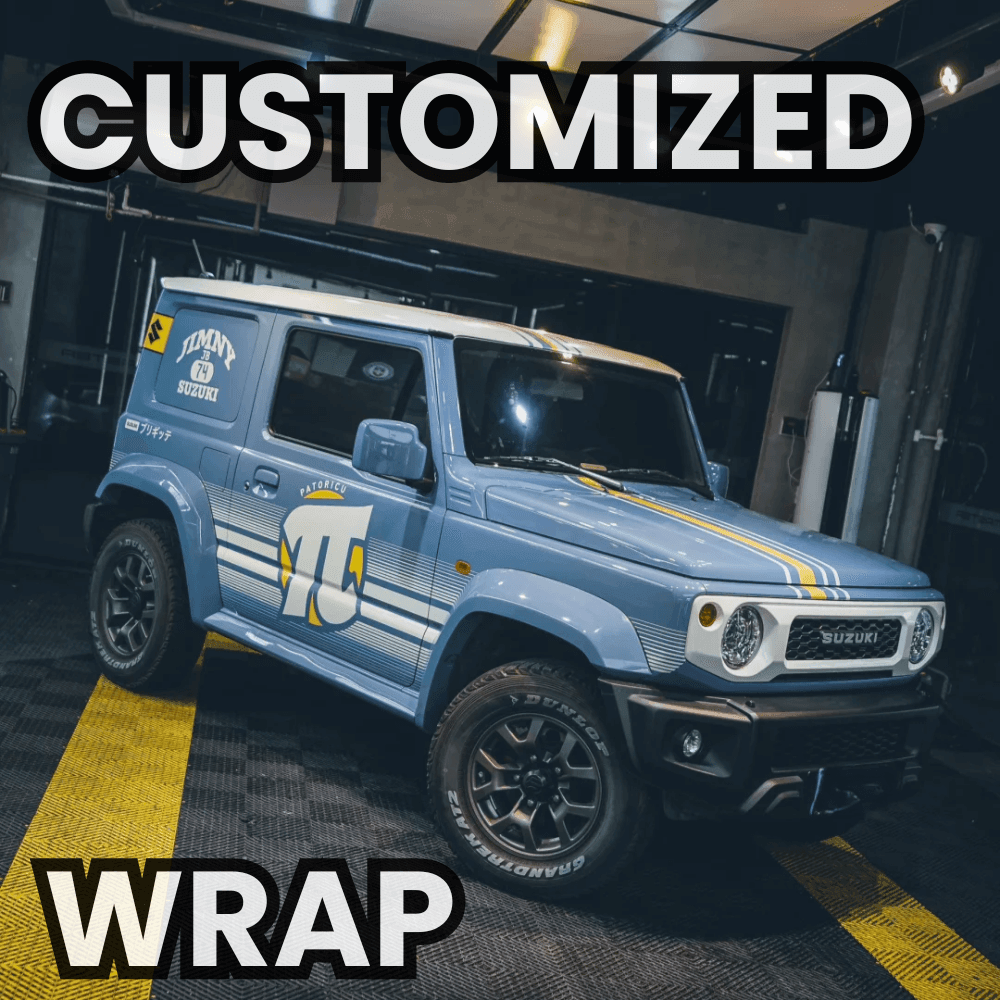

- Explore our collection of Customized Car Wraps to see how you can personalize your vehicle!

5. Air Release Technology

To ensure a seamless application process, calendared vinyl wraps are equipped with air release technology, which includes microchannels that allow trapped air to escape during installation:

-

Bubble-Free Finish: Reduces the chances of air bubbles forming beneath the wrap.

-

Ease of Application: Simplifies installation for both professionals and DIY enthusiasts.

6. Quality Assurance

Each batch of calendared vinyl undergoes rigorous quality checks before it reaches consumers. These assessments encompass critical factors such as:

-

Color Consistency: Ensures that each roll matches specified color standards.

-

Adhesion Strength: Tests how well the wrap adheres to various surfaces.

-

Overall Durability: Evaluates performance under different environmental conditions.

For high-quality options, check out our Best Sellers collection!

Calendered Vinyl Wrap Production Process: Step-by-Step Introduction

Step 1: Mixing Raw Materials

The production of calendered vinyl begins with mixing raw materials, primarily PVC, which forms the base of the vinyl. In addition to PVC, plasticizers, stabilizers, and pigments are added to enhance the material's flexibility, stability, and color. Plasticizers help make the vinyl more flexible and easier to apply, while stabilizers protect the vinyl from degradation caused by heat and UV exposure. Pigments are used to achieve the desired color for the vinyl wrap.

Step 2: Heating the Material

Once the raw materials are mixed, the PVC mixture is heated to achieve the consistency needed for the calendering process. The heating ensures the components are thoroughly blended and soft enough to be formed into a thin film. The temperature is carefully controlled to prevent the PVC from degrading while maintaining the right viscosity for further processing.

Step 3: Calendering Process

After heating, the PVC mixture is passed through a series of large, heated rollers in the calendering process. As the material moves between the rollers, it is flattened and thinned into a uniform film. The distance between the rollers controls the thickness of the vinyl wrap. This rolling process ensures consistency in the film’s thickness and smoothness, ensuring the production of high-quality vinyl suitable for wrapping.

Step 4: Cooling

Once the vinyl sheet has been formed, it must be cooled to solidify its structure and prepare it for the next steps. The cooling process stabilizes the vinyl, ensuring it maintains its desired thickness and shape. The cooling process is carefully controlled to avoid warping or unevenness in the film, in case affects its performance when applied.

Step 5: Application of Adhesives

After cooling, an adhesive layer is applied to the back of the vinyl film, making it suitable for wrapping applications. This adhesive ensures the vinyl adheres securely to surfaces like vehicles, walls, or signage. The adhesive we use is pressure-sensitive, meaning it activates when pressure is applied during installation, allowing for repositioning before a permanent bond forms.

Step 6: Printing or Finishing

Some calendered vinyl wraps undergo additional finishing processes, such as printing or adding texture. For example, vinyl wraps may be printed with custom designs, logos, or patterns, making them ideal for you for branding or advertising. Finishes like matte, gloss, or metallic can also be applied to create different visual effects and textures, depending on the intended use.

Step 7: Cutting and Packaging

Finally, the calendered vinyl sheets or rolls are cut to the required sizes and shapes based on customer needs, the standard roll of vinyl size is 5ft x 59ft that enough to fully wrap most sedan vehicles. The roll vinyl is packaged in the box for distribution, and properly protected during shipping and handling. Rolls of vinyl are typically packed to prevent any damage or creasing, ensuring they arrive ready for installation.

Empowering Personalization Through Yeswrap Vinyl Wraps

Calendared vinyl wraps empower vehicle owners and enthusiasts to unleash their creativity. Whether it’s a striking color shift effect or a sleek matte finish, these wraps offer a canvas for self-expression that goes beyond mere aesthetics.

Customization Options

Yeswrap provides an extensive range of customization options for their vinyl wraps, allowing customers to create a look that reflects their personal style or brand identity. Here are some of the key options available:

| Option | Description |

|---|---|

| Color Choices | A wide palette including metallics, glosses, mattes, and custom colors. This variety allows for unique combinations that can make any vehicle stand out. For example, customers can choose from collections like Gloss Blue or Chameleon Vinyl Wraps for vibrant transformations. |

| Textures | Options like brushed metal or carbon fiber finishes add depth to designs. These textures can enhance the visual appeal of vehicles, making them look more sophisticated and modern. Explore our Carbon Fiber Vinyl Wraps for a stylish option. |

| Patterns | Custom graphics or pre-designed patterns allow for unique personalization. Whether it's a bold graphic design or subtle patterns, the possibilities are endless. Check out our Customized Car Wraps collection for inspiration. |

Additional Insights:

- Statistics: According to industry reports, over 80% of vehicle owners who wrap their cars report increased satisfaction with their vehicle's appearance.

- Trends: The trend toward personalization is growing, with more consumers opting for vinyl wraps as a way to express individuality and stand out on the road.

Endless Possibilities with Calendared Vinyl Wraps

The allure of calendared vinyl wraps lies in their limitless possibilities beyond just automotive applications. These versatile materials can transform a variety of surfaces, making them a popular choice in numerous industries. Below, we will delve deeper into the diverse applications of calendared vinyl wraps, emerging market trends, and innovations that are shaping the future of this dynamic industry.

Applications Beyond Automotive

Calendared vinyl wraps can metamorphose various surfaces, providing creative solutions for both personal and commercial use. Here are some key applications:

1. Commercial Branding

Businesses utilize vehicle wraps for advertising purposes, transforming cars, trucks, and vans into mobile billboards. This method of branding is effective because it captures the attention of pedestrians and other drivers alike.

-

Statistics: According to the Outdoor Advertising Association of America (OAAA), vehicle wraps can generate between 30,000 to 70,000 impressions per day.

-

Case Study: A local pizza delivery service wrapped its fleet with vibrant graphics and saw a 15% increase in orders attributed to the visibility gained from their branded vehicles.

Explore our collection of Customized Car Wraps to see how you can enhance your business's visibility.

2. Architectural Elements

Vinyl wraps are increasingly used in architectural design to enhance both interior and exterior spaces. They can be applied to walls, furniture, and even windows to create stunning visual effects without the need for costly renovations.

-

Interior Design: Vinyl wraps can mimic textures such as wood grain or stone, offering an affordable alternative to traditional materials.

-

Exterior Applications: Buildings can be wrapped with vinyl to create temporary displays for events or promotions without permanent alterations.

Check out our Wood Grain Vinyl Wraps for unique interior design options.

3. Retail Branding and Marketing

Retailers leverage vinyl wraps for storefronts and product displays. They create eye-catching visuals that attract customers and reinforce brand identity.

-

Promotional Displays: Seasonal sales or new product launches can be highlighted using vibrant vinyl graphics that are easy to install and remove.

-

In-Store Branding: Vinyl wraps can be used on shelves, counters, and even floors to create a cohesive brand experience.

Discover our Best Sellers for popular choices in retail branding.

4. Event Décor and Theming

For event planners, vinyl wraps provide a flexible solution for creating immersive environments at trade shows, weddings, or corporate events. They can be used for backdrops, signage, and thematic decorations.

-

Quick Installation: Vinyl wraps can be applied and removed easily, making them ideal for temporary setups.

-

Customization: Event themes can be matched with custom graphics printed on vinyl wraps, enhancing the overall aesthetic appeal.

Explore our collection of Custom Vinyl Wraps to find options perfect for your next event.

5. Personalization and Customization

One of the most exciting aspects of vinyl wraps is their ability to be fully customized to meet individual users’ unique needs and preferences. Whether it’s a personalized laptop skin or a custom-designed smartphone case, vinyl wraps offer endless possibilities for personalization and self-expression.

Check out our Chameleon Vinyl Wraps for unique customizable options that stand out.

Market Trends and Innovations

The car wrap industry is continuously evolving with new trends and innovations that enhance the functionality and appeal of vinyl wraps:

1. Eco-Friendly Materials

With increasing environmental awareness, there is a growing demand for sustainable options in the vinyl wrap market. Manufacturers are exploring biodegradable materials that minimize environmental impact while maintaining quality.

-

Recyclability: Many modern vinyl wraps are designed to be recyclable at the end of their life cycle.

-

Non-Toxic Options: Innovations in material science have led to the development of non-toxic adhesives that are safer for both installers and consumers.

Explore our collection of eco-friendly options like Gloss Vinyl Wraps that combine style with sustainability.

2. Textured Finishes

Advancements in technology allow for more textured options that mimic natural surfaces like wood or stone. These textured finishes add depth and sophistication to designs:

| Texture Type | Description |

|---|---|

| Wood Grain | Offers a rustic look ideal for interiors |

| Stone Finish | Provides an elegant touch suitable for high-end applications |

| Metallic Effects | Adds shine and glamour to vehicles or displays |

Check out our Carbon Fiber Vinyl Wraps for a sleek metallic finish that enhances any project.

Common Myths About Calendered Vinyl Wraps

Calendered vinyl wraps are often misunderstood due to common myths surrounding their capabilities and limitations. Let’s clarify a few misconceptions to help you make informed decisions when choosing vinyl wraps for your project.

Myth 1: Calendered Vinyl Wraps Are Not Durable

Many people believe that calendered vinyl is not durable and won't hold up well over time. In reality, calendered vinyl wraps are highly durable, especially for outdoor use. While they may not last as long as cast vinyl in extreme conditions, they offer excellent resistance to UV rays, water, and abrasions, making them a reliable option for short to medium-term applications. When installed on appropriate surfaces, calendered vinyl can last several years, providing strong protection against the elements.

Myth 2: They Can Be Used on Any Surface

One of the most common misconceptions is that calendered vinyl wraps can be applied to any surface, including complex curves and deep recesses. However, this vinyl is best suited for flat or curved surfaces due to its thickness and rigidity. It may not conform well to highly contoured surfaces without a heat gun. For projects that involve intricate designs or 3D surfaces, cast vinyl is a better option. Calendered vinyl works perfectly on larger, flat areas like vehicles, trailers, and signage.

Myth 3: Calendered Vinyl Wraps Are Inferior to Cast Vinyl

Another myth is that calendered vinyl is simply a lower-quality product compared to cast vinyl. While it’s true that calendered vinyl is less conformable and may not last as long, it offers distinct advantages in terms of cost and ease of use. Calendered vinyl wraps are thicker and more rigid, making them easier to handle for applications on flat surfaces. They are also significantly more affordable, making them an excellent choice for budget-conscious projects or temporary wraps. Instead of being inferior, calendered vinyl is simply better suited for specific types of applications.

Myth 4: They Are Difficult to Install

Some believe that calendered vinyl wraps are hard to install, especially when compared to cast vinyl. In fact, calendered vinyl's added thickness can make it easier to install on flat or gently curved surfaces. Its rigidity reduces the risk of wrinkles and bubbles during application, making the installation process smoother. As long as the vinyl is applied to the right type of surface, installation is straightforward and efficient.

Myth 5: Calendered Vinyl Wraps Don’t Look Professional

There’s a misconception that calendered vinyl wraps lack the polished, professional look of other vinyl types. However, with proper installation and finishing, calendered vinyl can deliver a sleek, high-quality appearance. Available in a variety of finishes such as matte, gloss, and metallic, calendered vinyl wraps can achieve eye-catching results that rival more expensive materials. When used in the right context, calendered vinyl provides a professional, durable, and cost-effective solution.

Frequently Asked Questions (FAQs)

Q1: What exactly is a calendared vinyl wrap?

A1: A calendared vinyl wrap is a specialized material crafted through a calendaring process where vinyl is transformed into sheets with varying textures, thicknesses, and finishes designed for automotive and architectural applications.

Q2: How long does a calendared vinyl wrap last?

A2: The lifespan of a calendared vinyl wrap can vary based on factors such as climate, maintenance, and exposure to elements; generally, these wraps last around 3 to 5 years.

Q3: Can a calendared vinyl wrap be removed without damaging the underlying surface?

A3: Yes! When installed and removed by professionals, these wraps leave minimal residue and are unlikely to damage the original paint or surface underneath.

Q4: Are calendared vinyl wraps suitable for all types of vehicles?

A4: Absolutely! They can be applied to cars, trucks, motorcycles, boats, and even commercial fleets due to their flexibility.

Q5: How does air release technology work in calendared vinyl wraps?

A5: Air release technology incorporates microchannels that allow trapped air to escape during application, reducing air bubbles beneath the wrap.

Q6: Can calendared vinyl wraps be customized with unique designs or branding?

A6: Certainly! They can feature intricate designs or logos tailored to individual preferences or business branding needs.

Q7: Are calendared vinyl wraps suitable for outdoor applications?

A7: Yes! They are designed with UV protection to prevent fading from sunlight exposure.

Q8: How do I clean and maintain a calendared vinyl wrap?

A8: Regular washing with mild soap and water is recommended; avoid abrasive cleaners or harsh brushes that may damage the surface.

Q9: Can I install a calendared vinyl wrap myself?

A9: While DIY installation is possible, professional installation is highly recommended for optimal results due to expertise in achieving seamless application.

Q10: Where can I find various calendared vinyl wrap options?

A10: Visit Yeswrap's official website at yeswrap.com to explore diverse options available along with professional installation services.

Conclusion

Behind every calendared vinyl wrap is a symphony of craftsmanship, innovation, and artistry. The production process harmoniously blends technical expertise with creative passion—culminating in products that transform vehicles into unique masterpieces. With an array of finishes, textures, and colors available from Yeswrap’s offerings, these wraps provide endless possibilities for self-expression on the road and beyond.

By understanding how these innovative products are made—from material selection through quality assurance—consumers can make informed choices about their vehicle customization needs while appreciating the artistry involved in crafting each unique wrap.