Cast vs Calendered Vinyl

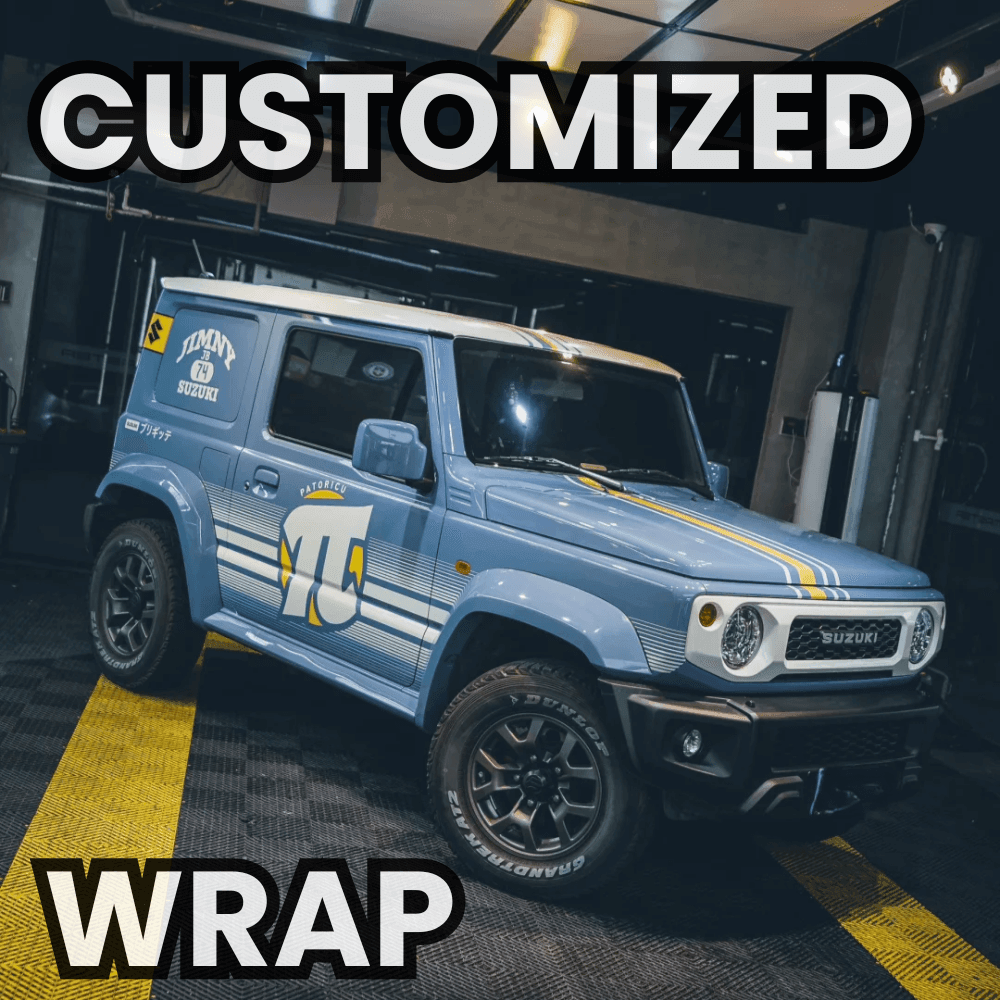

If you are not part of the signage or vehicle wrapping industry, you have probably never given much thought to the difference between cast and calendered vinyl. For most people, vinyl is simply a tool to achieve a visual or functional result. As long as it sticks and looks good, it seems like enough. However, with the growing demand for vinyl wraps in both professional and personal applications, understanding the distinction between these two materials has become essential.

Although cast and calendered vinyl start with similar base ingredients, the way they are manufactured leads to very different properties. Cast vinyl is produced through a process that creates a thin, highly flexible, and dimensionally stable film. This makes it ideal for long-term use and complex surfaces with curves and contours. In contrast, calendered vinyl is made by rolling and compressing the material, which results in a thicker and more rigid film that is best suited for flat or gently curved surfaces. It is also more affordable, making it a common choice for short-term projects or budget-conscious users.

The rise in popularity of vehicle wraps, custom decals, and decorative vinyl across industries has made the choice between cast and calendered film more important than ever. Using the wrong type can lead to poor results, including bubbling, edge lifting, and premature wear.

In this guide, we will explore everything you need to know about cast and calendered vinyl. We will look at how each type is made, their strengths and weaknesses, best use cases, and how to determine which one is right for your specific needs. Whether you are planning a full car wrap or a temporary window graphic, having the right knowledge will help you make the best decision.

The Basics of Cast and Calendered Vinyl

To understand the difference between cast and calendered vinyl, it’s important to first look at what they are made of. Both types of vinyl films begin with the same base material: polyvinyl chloride, or PVC. PVC is a versatile plastic that is naturally rigid, so it requires additional ingredients to become flexible and suitable for wrapping or signage applications.

Manufacturers add plasticizers to make the PVC flexible, along with dyes and pigments to create specific colors. Various additives are also included to enhance the film’s performance. These can include UV inhibitors to resist sun damage, heat stabilizers to prevent warping, and specialty agents that introduce unique properties such as reflectivity or gloss. The quality and combination of these materials can vary significantly depending on the intended use of the vinyl.

While the base components are similar, the production process is where cast and calendered vinyl begin to diverge. This process, along with the type of plasticizer used, plays a crucial role in the final product’s characteristics.

What Is Cast Vinyl?

Cast vinyl is a stable film that is made by pouring a liquid mixture of PVC and additives onto a casting sheet, which is then baked at a low temperature. It is widely regarded as the premium choice when it comes to vehicle wraps and other long-term graphic applications

How Cast Vinyl is Made

The production of cast vinyl begins with a liquid mixture composed of PVC resins, high-grade plasticizers, pigments, and stabilizing additives. This blend, often referred to as an organosol, is carefully mixed to ensure consistent quality. Once fully blended, the organosol is poured onto a casting sheet, which serves as a flexible base. The film then passes through a series of heated ovens, allowing the solvents to evaporate gradually. As the solvents are removed, the mixture solidifies into a thin, uniform film.

Because the material is not stretched or compressed during manufacturing, it experiences minimal internal stress. This results in a film that remains dimensionally stable, even when exposed to extreme temperatures or applied to curved surfaces. After the curing process, the finished film is coated with adhesive and wound onto large rolls for further use.

The casting sheet also plays a role in determining the surface texture of the vinyl. It can be engineered to produce finishes ranging from high-gloss to matte or even specialty textures like brushed metal or carbon fiber.

Key Features of Cast Vinyl

-

Ultra-thin construction: Typically between 1.5 to 2 mils thick, cast vinyl is much thinner than calendered vinyl, allowing it to blend seamlessly onto the surface.

-

Exceptional conformability: Because of its flexibility, it molds easily over rivets, curves, and complex contours, making it ideal for automotive wraps and other 3D surfaces.

-

Long service life: Depending on the brand and conditions, cast vinyl can last anywhere from 5 to 10 years.

-

Excellent color retention: High-quality pigments and UV inhibitors keep colors vivid and sharp even under prolonged sun exposure.

-

Weather and chemical resistance: Cast vinyl is engineered to withstand harsh environmental conditions, including heat, cold, moisture, and road debris.

Benefits of Cast Vinyl

Superior Durability: Cast vinyl films are built for longevity. Their formulation uses polymeric plasticizers, which are more stable and less prone to degradation over time. This contributes to greater resistance to cracking, shrinking, or peeling, especially when used outdoors.

Minimal Shrinkage: Because the material is formed in a stress-free environment, shrinkage after installation is significantly reduced. This means the edges of the wrap stay in place, and the film maintains its shape, even under heat or UV exposure.

Paint-Like Finish: Cast vinyl can deliver a smooth, high-quality appearance that mimics the look of automotive paint. Its thinner profile allows it to sit flush against the surface, creating a sleek and professional finish.

Superior Conformability: The thinness and flexibility of cast vinyl make it perfect for irregular surfaces. Whether it is a bumper, door handle, or fender, the film stretches and molds without distortion or bubbling.

Consistent Performance: Thanks to its manufacturing method and premium raw materials, cast vinyl maintains its visual and physical properties for years. It resists color fading, retains adhesive strength, and does not become brittle with time.

What Is Calendered Vinyl?

Calendered vinyl is a widely used material in the vehicle, graphics, and signage industry, especially for short- to mid-term applications. While it shares many of the same ingredients as cast vinyl, it follows a very different manufacturing process that results in a thicker, stiffer, and more cost-effective product. This makes it a practical choice for many projects where long-term performance and extreme flexibility are not required.

How Calendered Vinyl is Made

Calendered vinyl gets its name from the calendering process, which involves compressing the raw materials through a series of high-pressure rollers. The production begins by mixing PVC resin with plasticizers, pigments, stabilizers, and other additives. This mixture, often called a dry blend, is heated and fused together to form a homogenous mass, referred to as the melt.

Once formed, the melt is fed into counter-rotating heated rollers that flatten and stretch it into a sheet. These rollers operate at very high temperatures, often exceeding 300 degrees Fahrenheit. As the material moves through the rollers, it is shaped and thinned out according to specific requirements. The final step involves cooling and winding the film onto rolls, ready for adhesive application and finishing.

Because the material is stretched and manipulated during this process, it accumulates internal stress, which can lead to shrinkage or distortion after installation. Despite this, improvements in formulations and the use of polymeric plasticizers in higher-end calendered films have significantly enhanced their color options and overall performance.

Key Features of Calendered Vinyl

-

Thicker film: Typically ranges from 3 to 6 mils, offering added rigidity that makes the film easier to handle during installation.

-

Limited conformability: Best suited for flat or gently curved surfaces, as it does not stretch well around tight corners or complex shapes.

-

Shorter lifespan: Generally lasts between 3 to 5 years in outdoor conditions, although some premium formulations may perform longer.

-

More prone to shrinkage: Due to the stress introduced during production, calendered vinyl is more likely to pull back or lift at the edges over time.

Benefits of Calendered Vinyl

User-Friendly Handling: The added thickness and rigidity of calendered vinyl make it easier to install, especially for beginners or DIY users. It resists tearing and is more forgiving when repositioning during application.

Ideal for Flat Surfaces: Calendered films work best on flat or gently contoured surfaces such as windows, signs, walls, and vehicles with little curvature. This makes them a smart choice for promotional graphics or interior décor.

Cost-Effective: Compared to cast vinyl, calendered vinyl is more affordable. This makes it an excellent option for short-term projects, seasonal promotions, or any application where budget is a primary concern.

Improved Durability in Select Conditions: While calendered vinyl has a shorter outdoor lifespan, it performs well indoors or in environments with minimal exposure to extreme weather. Additionally, its thicker composition gives it greater resistance to abrasion, which is useful in high-traffic areas or on surfaces that experience frequent contact.

Flexible Quality Grades: Calendered vinyl is available in a range of quality levels. Economy-grade films use monomeric plasticizers and are intended for short-term use, while higher-end versions incorporate polymeric plasticizers, providing better stability and color retention.

Pros and Cons of Cast and Calendered Vinyl

Choosing between cast and calendered vinyl depends on your project’s requirements, expected lifespan, and surface complexity. Each type of vinyl offers its own set of advantages and limitations. Understanding the pros and cons of both will help you make an informed decision and avoid common installation or longevity issues.

Pros of Cast Vinyl

Long-Lasting and Premium Look: Cast vinyl is designed for long-term performance. It maintains its appearance and integrity over time, resisting fading, cracking, and peeling. The finish often mimics automotive paint, giving wraps a clean and professional appearance.

High Conformability: Thanks to its ultra-thin construction and stress-free manufacturing, cast vinyl easily conforms to complex surfaces. It wraps smoothly around curves, recesses, and rivets without wrinkling or lifting.

Resistant to UV and Weather: Cast vinyl includes high-quality stabilizers and UV inhibitors. This makes it highly resistant to sun damage, rain, snow, and temperature fluctuations, ensuring it performs well in harsh environments.

Cons of Cast Vinyl

Expensive: The production process and use of high-grade materials make cast vinyl more costly than calendered options. For large-scale or budget-sensitive projects, this can significantly increase costs.

Overkill for Short-Term Projects: While cast vinyl is ideal for long-term use, it may not be cost-effective for temporary applications. If your wrap or signage is only needed for a few months, the added durability may be unnecessary.

Pros of Calendered Vinyl

Affordable: Calendered vinyl is more budget-friendly, making it a practical option for short-term promotions, seasonal graphics, and simple decorative wraps.

Sufficient for Simple, Flat Applications: On flat or mildly curved surfaces, calendered vinyl performs well and is relatively easy to install. It works perfectly for windows, walls, signs, and flat vehicle panels.

Good for High-Turnover Custom Print Wraps: For wraps that will be frequently changed or updated, such as event branding or temporary product campaigns, calendared vinyl offers a reliable and economical solution.

Cons of Calendered Vinyl

Less Flexible for Complex Shapes: Calendered vinyl is thicker and stiffer, which makes it harder to apply to surfaces with curves, contours, or recesses. It may wrinkle or fail to adhere properly on complex geometries.

Shorter Durability: While it performs well in controlled environments, calendered vinyl typically has a shorter outdoor lifespan. It is more prone to shrinking, lifting, and fading when exposed to UV rays and harsh weather over time.

Cast vs. Calendered Vinyl: Which One To Choose?

Now that you understand the key differences between cast and calendered vinyl, the next step is determining which one is best for your project. This decision should not be based on price alone. Several important factors, such as durability, surface complexity, exposure to elements, and even installation skill, play a critical role in getting the result you want. Choosing the wrong type of vinyl can lead to early failure, poor aesthetics, and increased long-term costs.

To make the right choice, ask yourself the following questions:

How long do you need it to last?

If your wrap or graphic needs to hold up for five years or more, especially in outdoor conditions, cast vinyl is the safer and more dependable option. Its dimensional stability and resistance to fading or cracking make it ideal for long-term vehicle wraps, fleet branding, and exterior signage.

On the other hand, if your project is temporary or short-term, such as seasonal promotions, event signage, or a wrap that will be replaced within two or three years, calendared vinyl is usually more than sufficient. It provides good performance at a lower cost, especially for indoor or mildly exposed environments.

Is the surface flat, simply curved, or complex curved?

The more complex the surface, the more you will benefit from the flexibility of cast vinyl. If you're wrapping a car with deep contours, compound curves, or tight corners, cast vinyl will conform easily and remain in place without wrinkling or lifting.

For flat or lightly curved surfaces, such as window decals, wall graphics, flat vehicle panels, or basic signs, calendered vinyl is easier to handle and offers excellent visual results. It is thicker and more rigid, which also makes it a good choice for pre-spaced lettering or logo graphics, as it holds its shape better during application.

What’s your budget?

Cast vinyl tends to cost more due to its premium production process and long-lasting performance. However, it may offer better value in the long run if you want to avoid frequent replacements, especially for wraps exposed to sunlight, rain, or temperature changes.

If your priority is upfront savings and the project does not require high durability or flexibility, calendered vinyl is a smart choice. Many modern calendared films are made with better formulations and pigments, providing decent color stability and a respectable lifespan when used correctly.

Even with high-quality materials, the success of your wrap or graphic also depends on proper installation and maintenance. Many issues like edge lifting, shrinking, or fading are not just the result of low-grade vinyl, but of choosing the wrong type for the surface or conditions.

Myths and Misconceptions About Cast and Calendered Vinyl

When it comes to choosing between cast and calendered vinyl, many installers and DIY users are influenced by common myths that can lead to confusion or poor material selection. The truth is, both types of vinyl have specific strengths, and the best choice depends on how and where the film will be used. Let’s clear up some of the most common misconceptions.

“Calendered vinyl is not suitable for full vehicle wraps” – Not true

While cast vinyl is generally preferred for full wraps, especially on vehicles with complex curves, there are high-performance calendered vinyls that can be used effectively for full wraps on flat or gently contoured surfaces. With the right installation techniques and surface preparation, calendered vinyl can work well on box trucks, trailers, and even some passenger vehicles where extreme flexibility is not required.

"Calendered vinyl is always bad and cheap" – It’s great for the right job

Not all calendered vinyl is created equal. There are different grades, from economy to intermediate to high-quality polymeric calendered films. While basic calendered vinyl is best for short-term use, modern calendered films offer excellent print quality, durability, and appearance for indoor signage, window graphics, wall decals, and flat-surface wraps. When chosen appropriately, calendered vinyl can offer excellent value without sacrificing quality.

“Cast vinyl always looks better” – Depends on surface and color

Cast vinyl is known for its thin profile and paint-like finish, but that does not automatically mean it will look better in every situation. Color, finish type, and application surface all play a role in final appearance. In many cases, calendered vinyl with a gloss or satin finish can look just as clean and vibrant on flat surfaces or short-term wraps. Appearance is also heavily influenced by lighting, angle, and the quality of installation.

“All vinyl shrinks” – Cast shrinks far less

Vinyl can indeed shrink over time, especially under sun exposure or heat. However, cast vinyl is manufactured without mechanical stress, making it far more dimensionally stable. Shrinkage is minimal and often unnoticeable, which is why it is preferred for long-term use. Calendered vinyl, on the other hand, goes through a rolling process that builds in internal tension, so it is more prone to pulling back at edges or shrinking along seams if not properly installed and maintained.

Final Thought

When it comes to choosing between cast and calendered vinyl, there is no one-size-fits-all answer. Each type of vinyl has strengths that make it the better choice for specific situations. The right decision comes down to your application needs, surface complexity, desired lifespan, and overall budget.

Cast vinyl stands out for its ability to conform smoothly over complex curves, its resistance to UV and weather, and its excellent long-term performance. If your project involves deep contours or outdoor exposure for five years or more, cast vinyl offers the reliability and finish that professionals trust.

Calendered vinyl, on the other hand, is a smart and cost-effective choice for full vehicle wraps. It handles well, performs reliably on flat or lightly curved surfaces, and delivers solid visual appeal at a lower price point. For short-term branding, seasonal graphics, or DIY projects, calendered film can provide excellent value without compromising quality when used correctly.

Ultimately, the best vinyl is the one that aligns with your project goals. By understanding the differences in this article and assessing your specific requirements, you can choose a material that delivers both the performance and the results you’re looking for.

Ready to Wrap?

Explore premium, affordable calendered vinyl at Yeswrap today. Whether you're working on signage, decals, or a full vehicle project, our high-quality films deliver great performance and value. Find the perfect finish for your next wrap—shop now and get fast, free shipping on every order.

Related Articles:

How to Choose the Right Vinyl Wrap Material for Your Car

How Are Yeswrap Vinyl Wraps Made?

The Difference Type of Vinyl Wrap

The Ultimate Guide to Colored PPF

Vinyl Wrap vs Paint Protection Film | How To Choose?