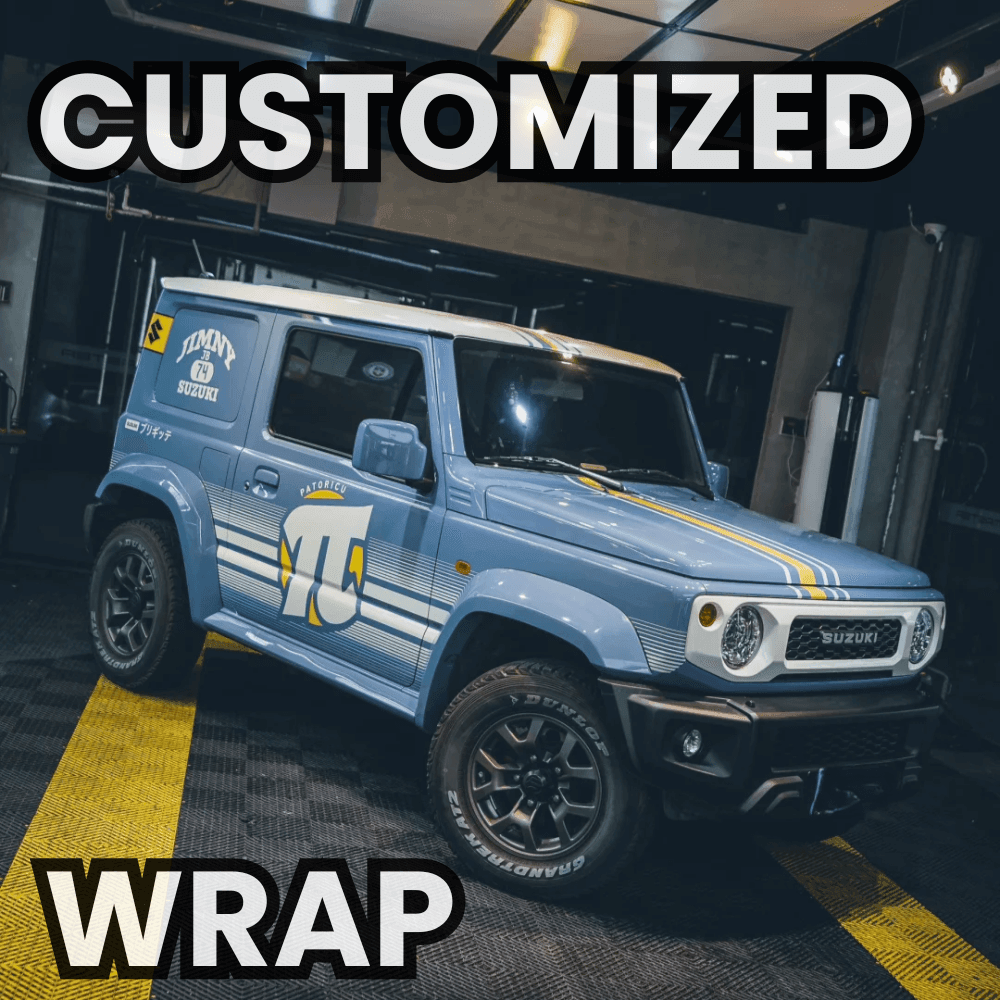

How to Choose the Right Vinyl Wrap Material for Your Car

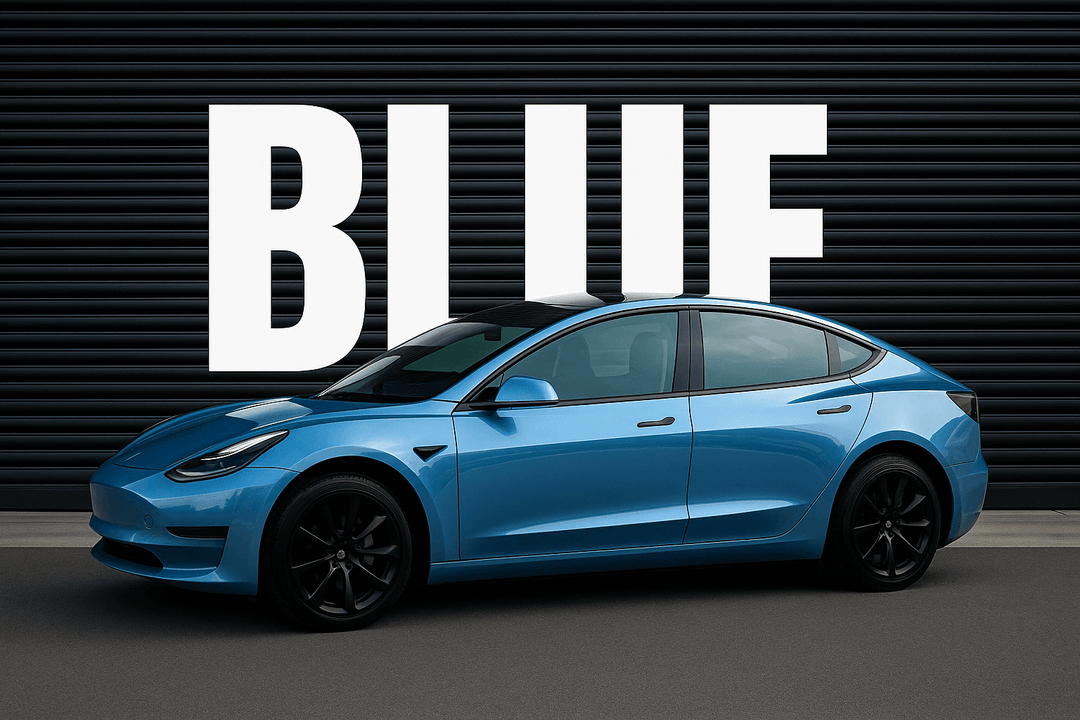

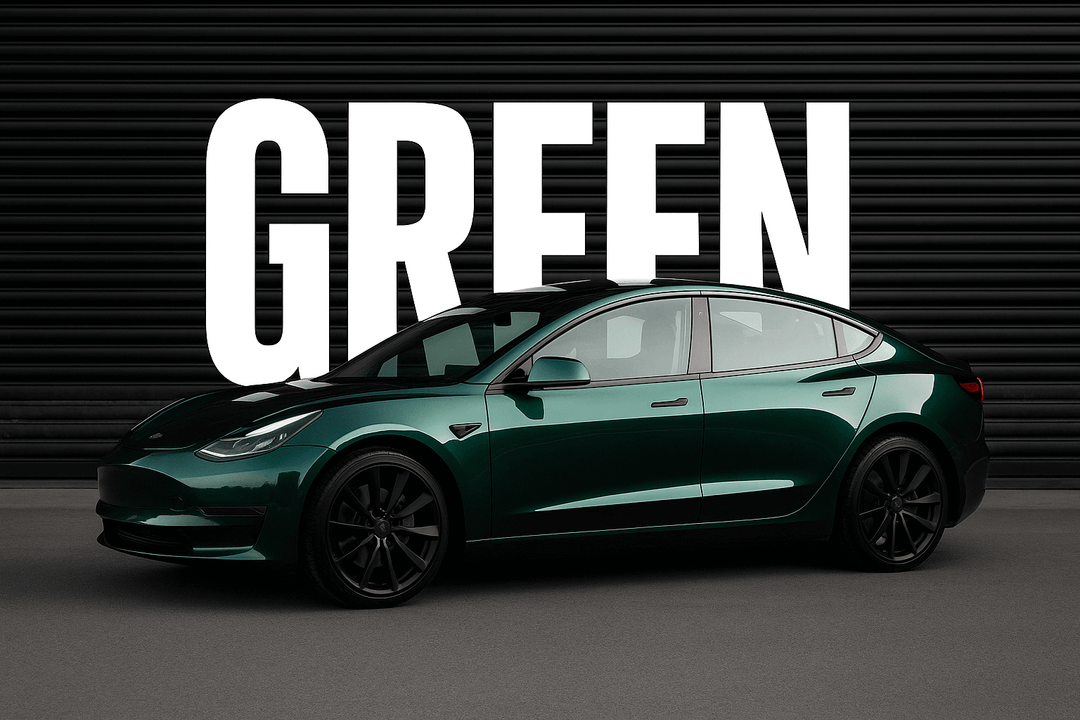

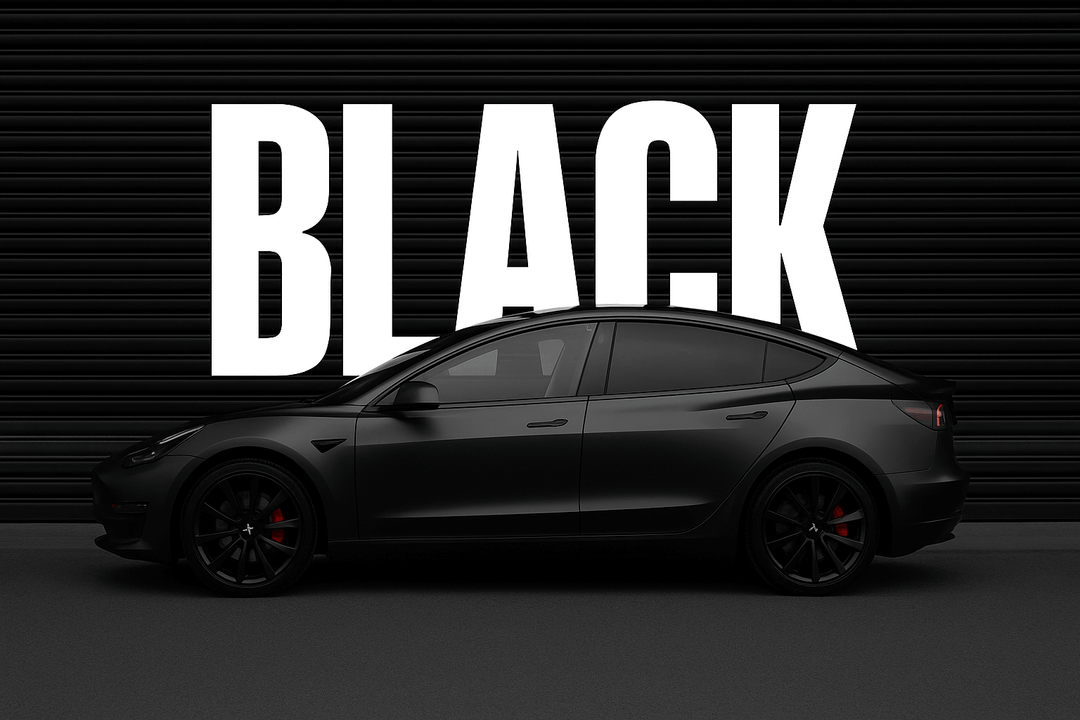

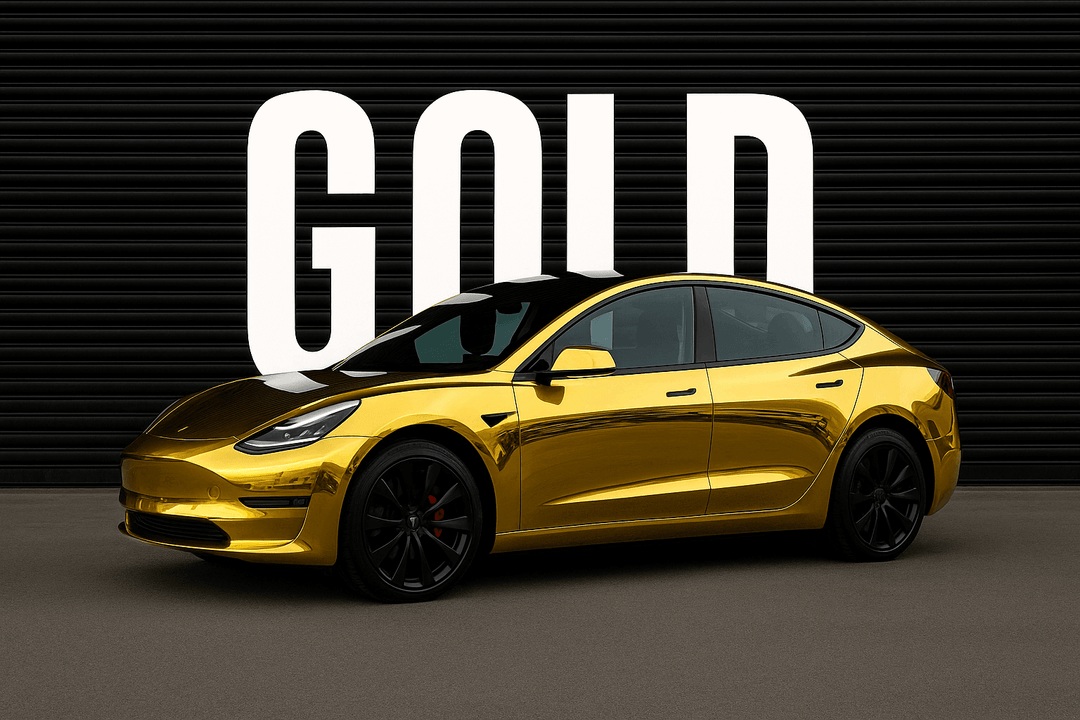

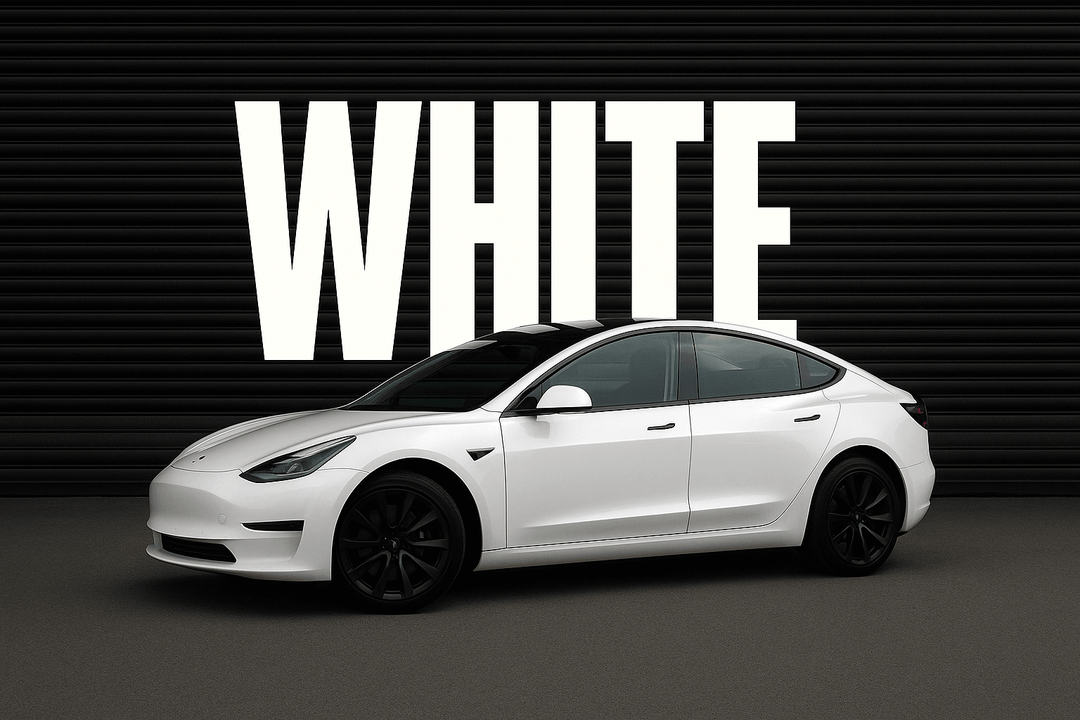

Wrapping your car is one of the most effective ways to change its appearance while protecting the original paint. However, before exploring colors, textures, or finishes, it is important to understand how to choose the right vinyl wrap material for your car.

The material you select plays a key role in how the wrap performs, how it looks over time, and how well it fits your specific needs. Some wraps are designed for short-term use or simple applications, while others offer long-lasting durability and advanced flexibility for complex surfaces.

This guide will help you understand the key differences between types of vinyl wrap materials, including their strengths, finishes, and best use cases. Whether you are planning a full vehicle wrap or applying custom accents, this article will give you the knowledge to make a confident, informed decision.

What Is Vinyl Wrap Material?

Vinyl wrap material is a specialized automotive film used to restyle and protect the exterior or interior surfaces of a vehicle. It has become a popular alternative to traditional paint jobs, offering drivers a way to customize their car's appearance without the permanence, cost, or downtime associated with repainting.

Unlike paint, which is sprayed directly onto the vehicle and bonded to the surface, vinyl wrap is a thin, flexible film that is applied on top of the existing finish. It can be removed without damaging the original paint, making it a reversible and less invasive customization option. This flexibility is especially useful for leased vehicles or owners who want to update their style without committing to a full respray.

Vinyl wrap material is composed of multiple layers that work together to deliver both visual appeal and durability:

-

Topcoat layer: This clear layer provides protection against UV rays, minor scratches, and environmental wear. It also contributes to the wrap’s finish, whether gloss, matte, satin, or textured.

-

Color or pattern layer: This is where the visual effect is created. It may feature a solid color, metallic flake, printed design, or color-shifting pigments, depending on the style of the wrap.

-

Adhesive layer: On the back of the vinyl, a pressure-sensitive adhesive allows the wrap to bond securely to the surface while still being removable. High-quality wraps often include air-release channels that make installation smoother and help eliminate bubbles.

The Types of Vinyl Wrap: Cast vs. Calendared Vinyl

When choosing vinyl wrap material, one of the most important decisions you will make is whether to use cast or calendared vinyl. These two types differ significantly in terms of manufacturing process, flexibility, durability, and ideal application.

Cast Vinyl Wrap

Cast vinyl is considered the premium option in the vinyl wrap industry. It is manufactured by pouring liquid vinyl into a flat mold and then curing it into a thin, flexible film. This process creates a material that is extremely lightweight, smooth, and easy to conform to the contours of a vehicle.

Key features of cast vinyl wrap:

-

Thin and lightweight: Allows for a paint-like finish with minimal texture

-

Highly conformable: Ideal for wrapping complex curves, edges, and recessed areas

-

Durable: Resistant to shrinking and fading over time

-

Long-lasting: With proper care, cast vinyl wraps can last up to seven years or more

Cast vinyl is the preferred choice for full vehicle wraps, particularly when professional results and long-term use are priorities. It provides a seamless appearance and holds up well under a wide range of weather conditions, making it a reliable option for both personal and commercial vehicles.

Calendared Vinyl Wrap

Calendared vinyl is a more budget-friendly option, often chosen for short-term projects or DIY applications. It is produced by rolling and stretching the vinyl through heated rollers, which results in a thicker, less flexible film compared to cast vinyl.

Key features of calendared vinyl wrap:

-

Thicker material: Offers good coverage but is less conformable on complex shapes

-

Affordable: Ideal for cost-conscious projects or temporary use

-

Best for flat or lightly curved surfaces: Performs well on hoods, roofs, doors, and panels

-

DIY-friendly: Easier to handle for beginners working on small sections

-

Moderate durability: With proper care, calendared vinyl can last three to five years

While calendared vinyl does not offer the same level of flexibility or long-term durability as cast vinyl, it is a practical choice for accent wraps, simple restyling, or temporary advertising. It also serves as a great choice for those new to vehicle wrapping or working on a limited budget.

Factors to Consider When Choosing a Wrap Material

Selecting the right vinyl wrap involves more than just choosing a color or finish. You need to consider the material's performance, durability, and compatibility with your vehicle's surface.

1. Vinyl Wrap Durability and Lifespan

Durability is one of the most important considerations when choosing a vinyl wrap, especially if you are planning a full vehicle wrap or want the finish to last for several years.

Cast vinyl wraps are known for their superior longevity. They resist shrinking, cracking, and fading even under exposure to sunlight, rain, and fluctuating temperatures. When professionally installed and properly maintained, cast wraps can last up to seven years or more without significant wear.

Calendared vinyl wraps, on the other hand, are better suited for short-term or budget-conscious applications. They are thicker and less conformable, which makes them more vulnerable to lifting or edge failure over time, especially on curved or complex surfaces. On average, calendared wraps offer a lifespan of three to five years.

2. Your Budget

If you’re working with a limited budget or planning a short-term wrap, calendared vinyl is often the better choice. It is more affordable and well-suited for flat surfaces or DIY projects. While it may not offer the same level of durability as premium options, it still provides good visual impact at a lower price point.

If you’re investing in a full vehicle wrap and want a finish that lasts for years with minimal maintenance, cast vinyl is worth the higher upfront cost. It provides a better conformability, a smoother paint-like appearance, and a longer lifespan.

3. Installation Surface (Flat or Lightly Curved vs. Complex Curves)

If your project involves flat panels or lightly curved surfaces, such as doors, hoods, or roofs, a calendared vinyl wrap may be sufficient. While thicker and less flexible, calendared vinyl works well on large, simple surfaces and is often preferred for short-term projects or DIY wraps.

However, if you are wrapping areas with deep curves, recesses, edges, or complex body lines, such as bumpers, side mirrors, or fenders, cast vinyl is the superior choice. Its thin and highly conformable nature allows it to stretch smoothly over curves without lifting, bubbling, or wrinkling.

4. Durability Needs (UV, Rain, Heat Resistance)

High-quality cast or calendared vinyl wraps are designed to handle long-term exposure to UV rays, moisture, and temperature fluctuations. They retain their color, resist fading, and maintain adhesion even in demanding climates. For vehicles exposed to direct sunlight regularly, a cast vinyl with built-in UV protection helps prevent discoloration and material degradation.

Most automotive-grade wraps are waterproof, but premium materials offer stronger protection against edge lifting and mold buildup. Cast vinyls are better equipped to handle thermal expansion and contraction, reducing the risk of cracking or bubbling in extreme conditions than calendared vinyl.

5. Adhesive Quality

A high-quality adhesive ensures the wrap bonds securely to your vehicle’s surface during installation and remains in place under daily use. Look for wrap materials that feature a pressure-sensitive adhesive with air-release technology.

These adhesives are designed to create strong, even contact with the vehicle while allowing air to escape through tiny channels. This not only helps avoid bubbles but also makes the film easier to reposition during installation. A clean-removal adhesive allows the vinyl to peel away without damaging the original paint or leaving behind sticky residue.

Why Choose Yeswrap Vinyl Wraps?

At Yeswrap, we combine cutting-edge material technology with a wide selection of finishes to deliver wraps that meet the needs of both professionals and everyday drivers.

Premium Multilayer Polymeric Calendared Vinyl

Our vinyl films are crafted with high-grade polymeric materials that provide enhanced flexibility, strong durability, and a consistent finish. The multilayer structure adds stability, making the material easier to handle and more resistant to shrinkage over time.

UV and Weather Resistance

Whether you drive in hot sunlight, heavy rain, or fluctuating weather conditions, Yeswrap vinyl wraps are engineered to last. Each film is treated for UV protection and built to resist cracking, fading, and peeling, helping to preserve your wrap’s color and appearance for years.

Air-Release Adhesive for Bubble-Free Install

Our wraps feature advanced air-release channel technology, allowing installers to apply the material smoothly with fewer bubbles or wrinkles. This makes the installation process cleaner and more efficient, whether you're working on a full wrap or a detailed accent.

TPU-Based Color PPF for Up to 10 Years

For those who want paint protection along with vibrant color, our TPU-based color paint protection film (PPF) offers a premium solution. With self-healing properties and color-infused layers, this film protects your vehicle while delivering a stunning, glossy finish that lasts up to 10 years.

Affordable Pricing and Fast Free Shipping

Yeswrap believes that premium quality should be accessible. We offer competitive pricing across all product lines, along with fast and free shipping, so you can get started on your project without delays or added cost.

Final Thought

While choosing the right vinyl wrap material is a key part of any successful vehicle wrap project, the quality of installation is just as important. Even the highest-grade cast vinyl may underperform if applied incorrectly. A professional installer ensures proper surface preparation, clean edges, and smooth application—all of which directly affect the lifespan and appearance of the wrap.

It is also worth noting that even durable cast vinyl films should be monitored and maintained over time. For example, after three to four years of exposure to sunlight and weather, it is often recommended to remove and reapply the wrap, even if the material appears intact. Prolonged UV exposure may cause the adhesive to bond more strongly to the paint, making removal more difficult and increasing the risk of residue or surface damage.

To get the most out of your investment, always start with high-quality vinyl that is designed specifically for vehicle use. Look for materials that are thick, flexible, and equipped with strong, clean-removal adhesives. When combined with professional installation and regular maintenance, a premium vinyl wrap will deliver long-lasting results in both style and protection.

Trying to find the perfect wrap for your car?

Explore Yeswrap’s full collection of high-performance vinyl wrap materials and finishes. Whether you’re aiming for a bold color transformation, subtle texture upgrade, or added protection for your paint, we offer the quality and variety to match your vision.

Shop now and discover wraps that are built for durability, easy installation, and standout visual impact—backed by fast, free shipping and professional support.

Related Articles:

How Are Yeswrap Vinyl Wraps Made?

The Difference Type of Vinyl Wrap

The Ultimate Guide to Colored PPF

Vinyl Wrap vs Paint Protection Film | How To Choose?