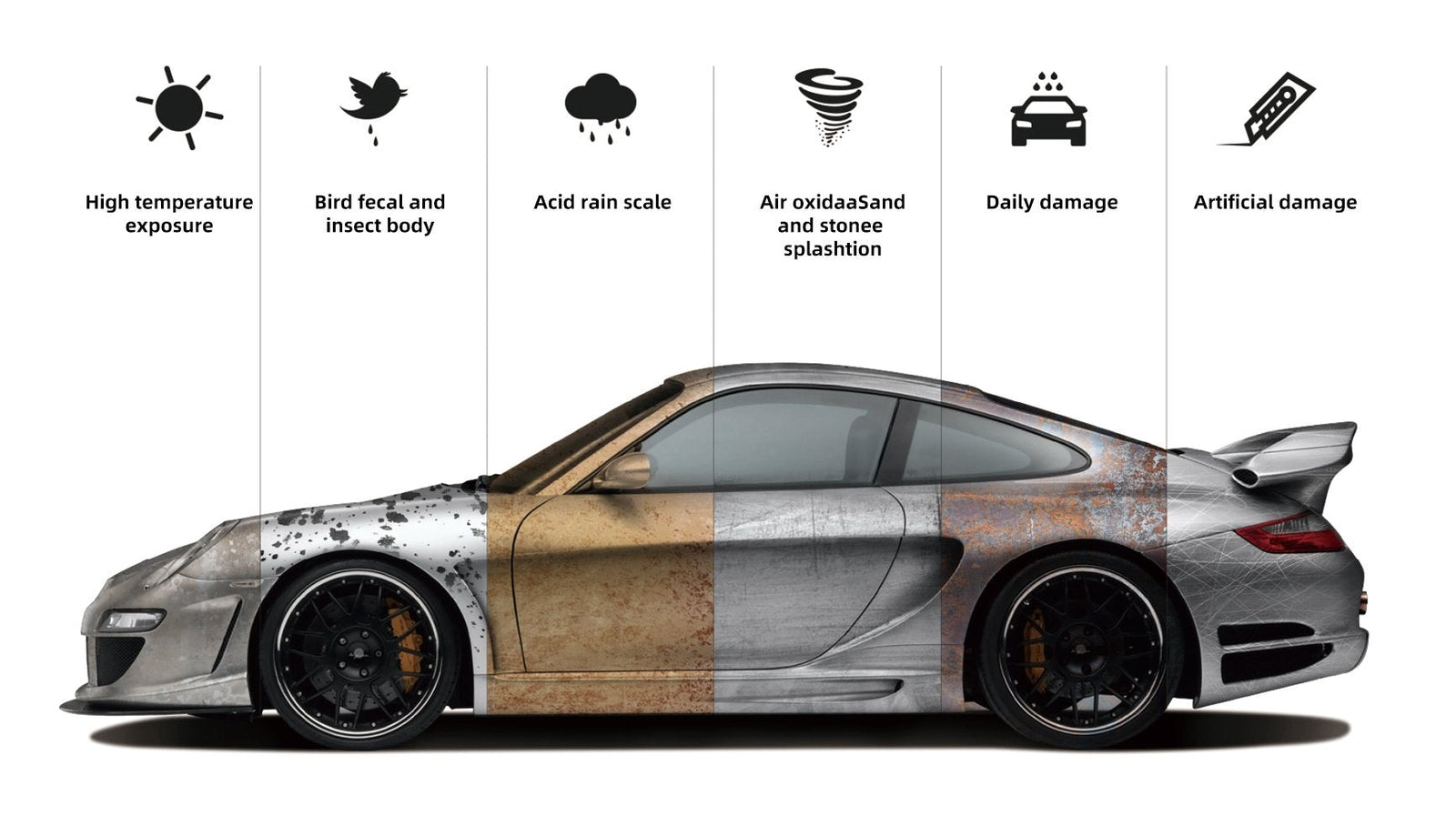

Protect Original Paint

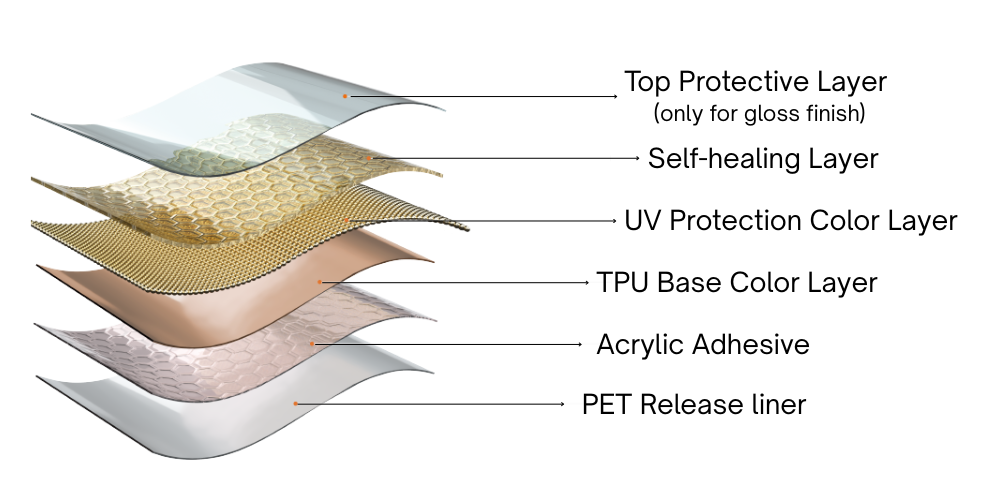

Color PPF Structure

Why Choose YESWRAP Color PPF?

Give your vehicle a clean, polished, and timeless upgrade with the Glossy White Color PPF from Yeswrap. This premium paint protection film delivers a bright white finish with refined gloss, creating a smooth and modern appearance that enhances any vehicle style. Designed with advanced TPU technology, it provides strong protection against daily wear while keeping your car looking fresh, crisp, and elegant.

Clean Glossy White Finish

This Glossy White Color Paint Protection Film features a pure white tone with a smooth high-gloss surface that reflects light evenly. This creates a clean and sophisticated appearance that highlights your vehicle’s body lines with clarity. Gloss white is a classic and versatile color that works well on sedans, SUVs, EVs, sports cars, trucks, and luxury models. It offers a bright and professional look that never goes out of style.

Durable TPU Paint Protection

This PPF uses strong TPU material to protect your vehicle from scratches, stone chips, and road debris. It offers reliable defense against UV exposure and oxidation, helping maintain long-term color stability and gloss. The hydrophobic coating repels water, dust, grease, and dirt, making the bright white surface easy to clean and maintain.

Self-Healing Surface

Our Glossy White Color PPF comes with a self-healing top layer that repairs fine scratches and swirl marks when exposed to heat or sunlight. This keeps the high-gloss surface smooth and even, reducing the need for frequent polishing and helping your vehicle maintain a freshly detailed appearance.

Smooth and Bubble-Free Installation

Installation is simple thanks to integrated air-release channels. These channels prevent air pockets and allow the film to settle smoothly across flat panels, curves, and complex shapes. The TPU material conforms easily to edges and contours. The adhesive supports both wet and dry installation and allows repositioning for precise and seamless alignment.

Long-Lasting Durability

With proper care, this PPF provides up to ten years of strong performance. It resists yellowing, cracking, peeling, and fading, helping maintain the clean white finish through various climates and daily use. Built for clarity and durability, it protects the paint while keeping the glossy white surface bright and consistent.

Key Features

-

Glossy finish with pure white tone

-

High-performance TPU material

-

Self-healing topcoat repairs light scratches

-

Hydrophobic surface repels dirt and water

-

UV, oxidation, and corrosion resistant

-

Non-yellowing and fade-resistant

-

Air-release channels for bubble-free installation

-

Suitable for wet and dry application

-

Scratch-resistant and crack-resistant

-

Lifespan up to 10 years with proper maintenance

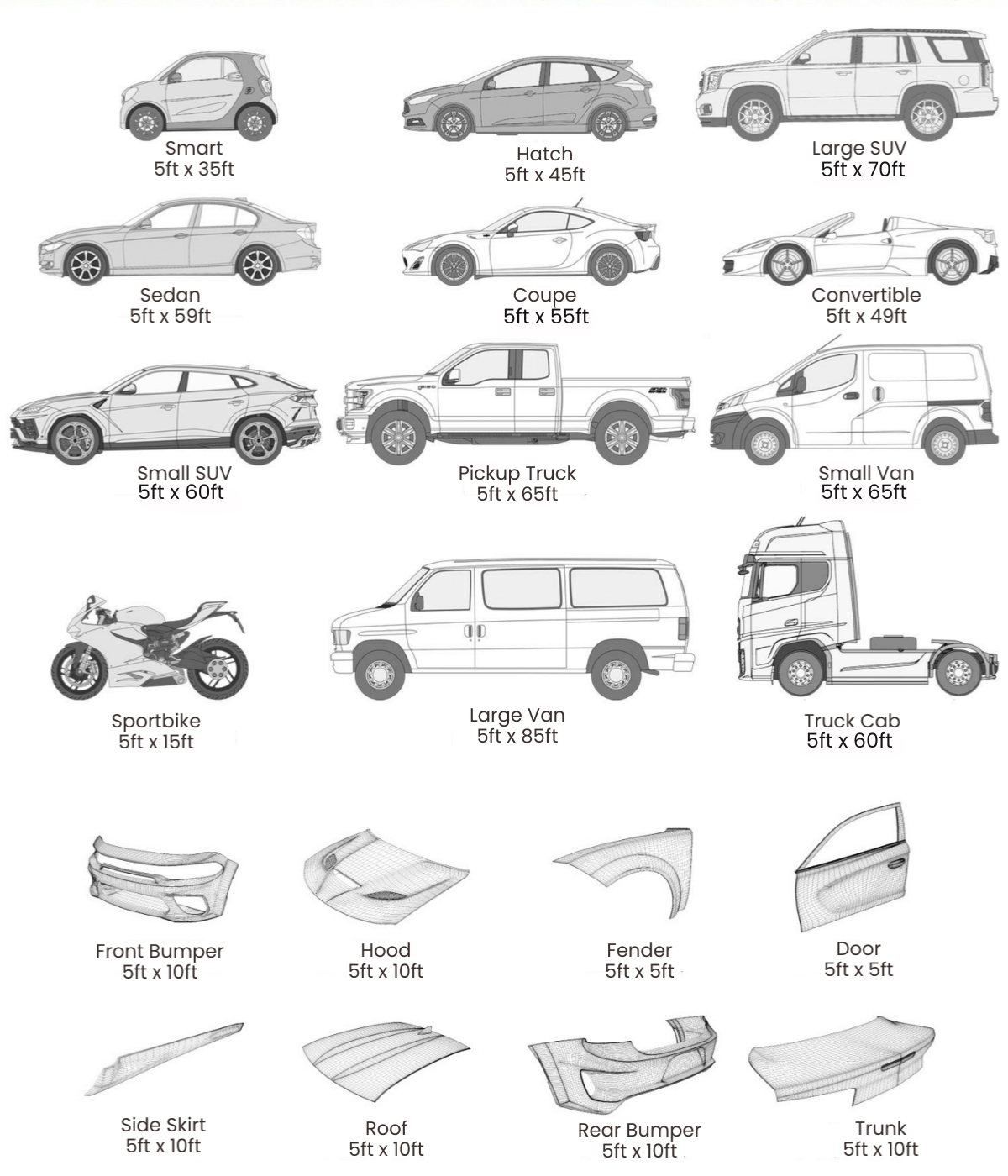

Specifications

-

Color: Gloss White

-

Finish: Gloss

-

Material: TPU (Thermoplastic Polyurethane)

-

Application Method: Wet/Dry

-

Sizes Available: 5ft x 10ft, 16ft, 33ft, 49ft, 59ft, 69ft

Why Choose Yeswrap

Yeswrap’s Glossy White Color PPF is ideal for drivers who want a clean, bright, and professional look backed by durable protection. It offers smooth installation, long-lasting clarity, and high-gloss performance that elevates any vehicle.

Upgrade your vehicle with the Glossy White Paint Protection Film from Yeswrap. Order today and enjoy a crisp and polished finish that stays beautiful for years.