Can the Tesla Cybertruck Be Painted?

Many Tesla Cybertruck owners ask the same question soon after taking delivery: can the Cybertruck be painted? Instead of painted body panels, Cybertruck features an ultra-hard stainless steel exoskeleton designed for durability and corrosion resistance. This material behaves very differently from conventional automotive steel or aluminum, which makes standard painting methods far less suitable.

While painting a Cybertruck may sound like a straightforward solution, it is rarely practical in reality. The process is complex, costly, and can compromise the steel’s protective properties. Fortunately, there are more effective alternatives. Vinyl wraps and color-change paint protection film offer flexible, removable ways to achieve almost any color or finish without damaging the stainless steel underneath.

What Makes the Tesla Cybertruck Different?

The Tesla Cybertruck stands apart from every other pickup on the road, largely because of how it is built. Its design and materials redefine traditional vehicle construction, which directly affects how it can be customized.

Instead of using conventional steel or aluminum panels covered in paint, the Cybertruck features an ultra-hard stainless steel exoskeleton. This material is engineered for strength, impact resistance, and long-term durability. It is not coated with paint at the factory, giving the truck its raw, industrial appearance.

Because there are no traditional painted body panels, the Cybertruck avoids many issues associated with chipped or fading paint. The stainless steel surface also provides built-in corrosion resistance, meaning it does not rely on paint layers to protect it from rust or environmental damage.

Why Traditional Painting Is Not Practical for the Cybertruck

Although painting seems like the most familiar way to change a vehicle’s appearance, it is not a practical solution for the Tesla Cybertruck. The truck’s stainless steel construction creates several technical and long-term issues that make traditional paint both risky and inefficient.

Poor Paint Adhesion on Stainless Steel

Automotive paint is designed to bond to surfaces that accept primer easily. Untreated stainless steel does not provide that surface. Paint struggles to adhere properly unless the steel is heavily prepared. This usually requires aggressive sanding or chemical etching to create enough texture for the paint to stick. Without these steps, the finish is likely to fail prematurely.

Loss of Corrosion Protection

One of the biggest drawbacks of sanding stainless steel is that it removes the material’s natural protective layer. That layer is what gives the Cybertruck its corrosion resistance in the first place. Once it is stripped away, the steel becomes more vulnerable to moisture and environmental exposure. Over time, this can increase the risk of rust and corrosion, especially in harsh climates.

Durability Problems After Painting

Even with extensive preparation, painted stainless steel does not perform as well as painted aluminum or traditional automotive steel. The finish is more prone to chipping, flaking, and cracking. Impacts from road debris that would normally cause minor paint damage can lead to more noticeable failure on a painted Cybertruck.

Cost and Complexity

Painting a Cybertruck requires far more labor than painting a conventional vehicle. The preparation alone is time-consuming and demands specialized expertise. This drives costs significantly higher, often far beyond what most owners expect. If the final result is not satisfactory, reversing the process is difficult and expensive, making painting a high-risk choice.

For these reasons, traditional painting is generally considered impractical for the Cybertruck; however, you can choose a safer and more flexible alternative - a car wrap.

Best Alternatives to Painting a Cybertruck

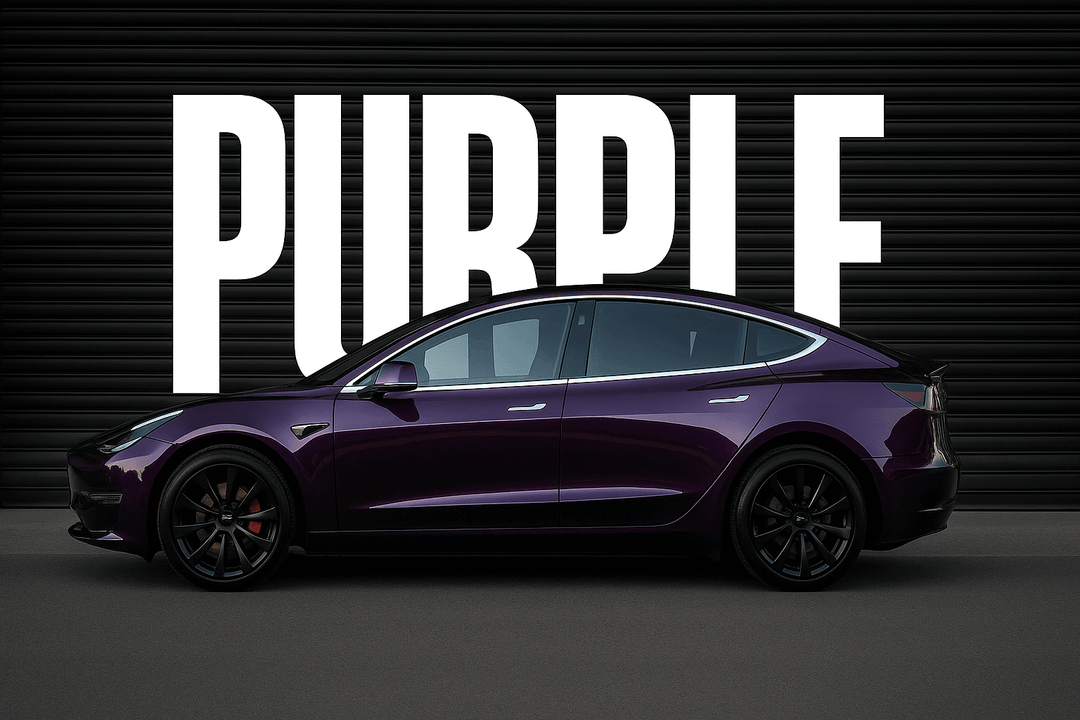

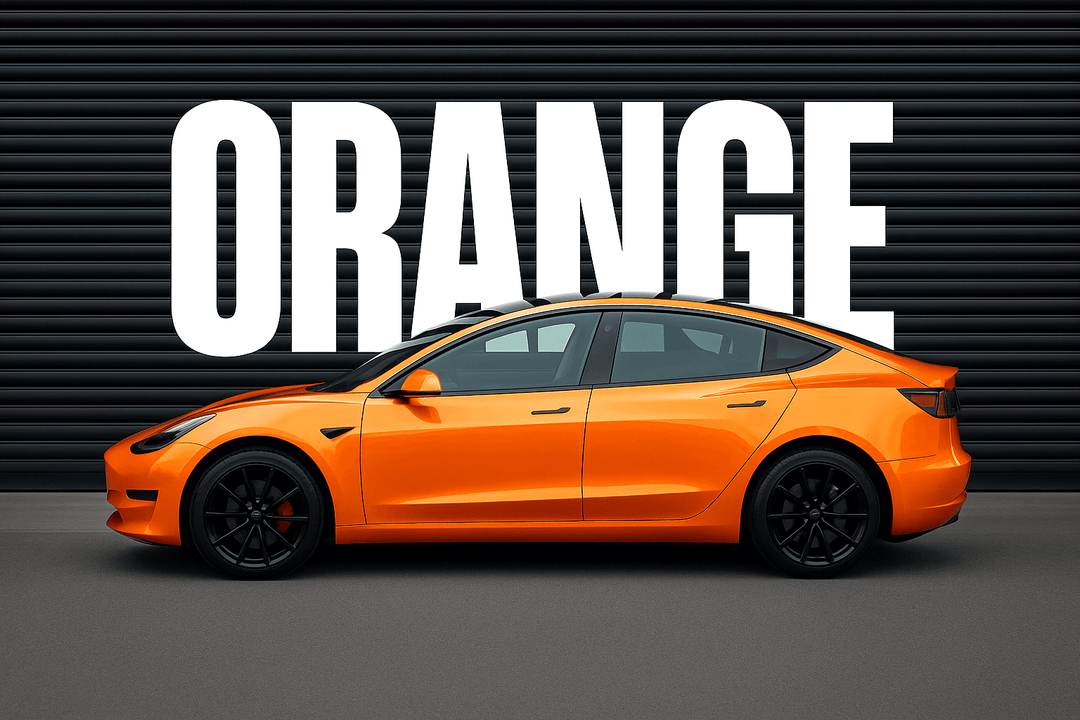

Since traditional paint is not well suited for the Cybertruck, most owners turn to surface films that offer both customization and protection. These alternatives allow you to change the truck’s appearance without damaging the stainless steel underneath.

1. Vinyl Wraps

What Is a Vinyl Wrap?

A vinyl wrap is a thin, adhesive film applied over the exterior surfaces of the vehicle. It changes the color or finish without altering the original material. Vinyl wraps are designed to sit on top of the stainless steel, making them a non-invasive and reversible solution.

Pros of Vinyl Wraps

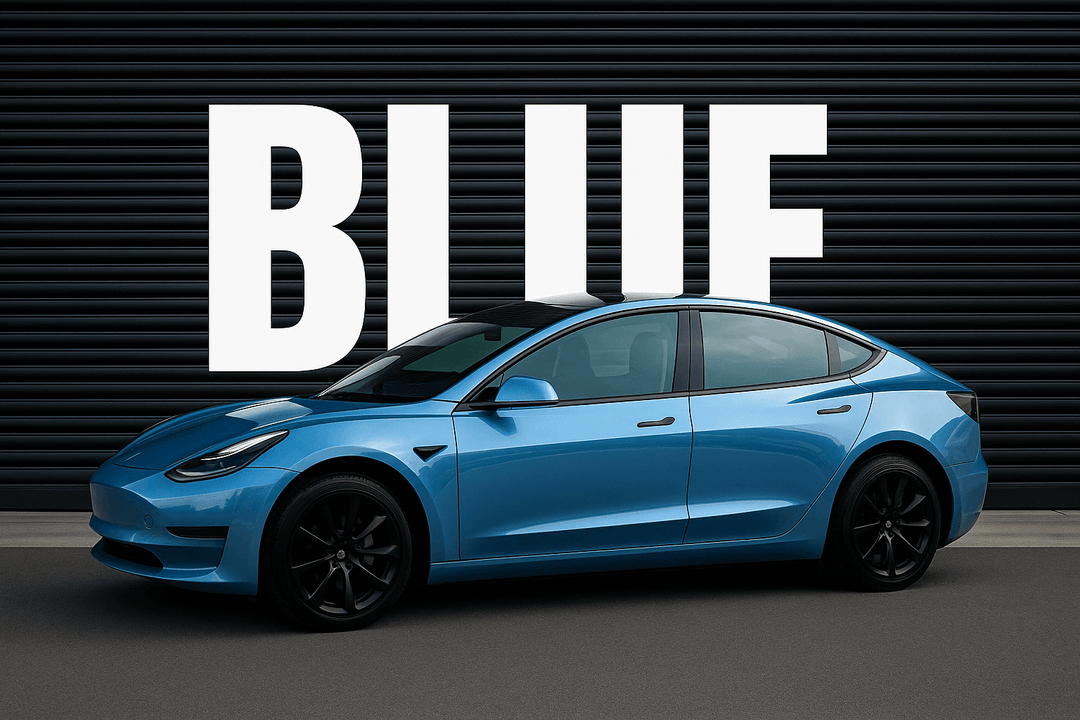

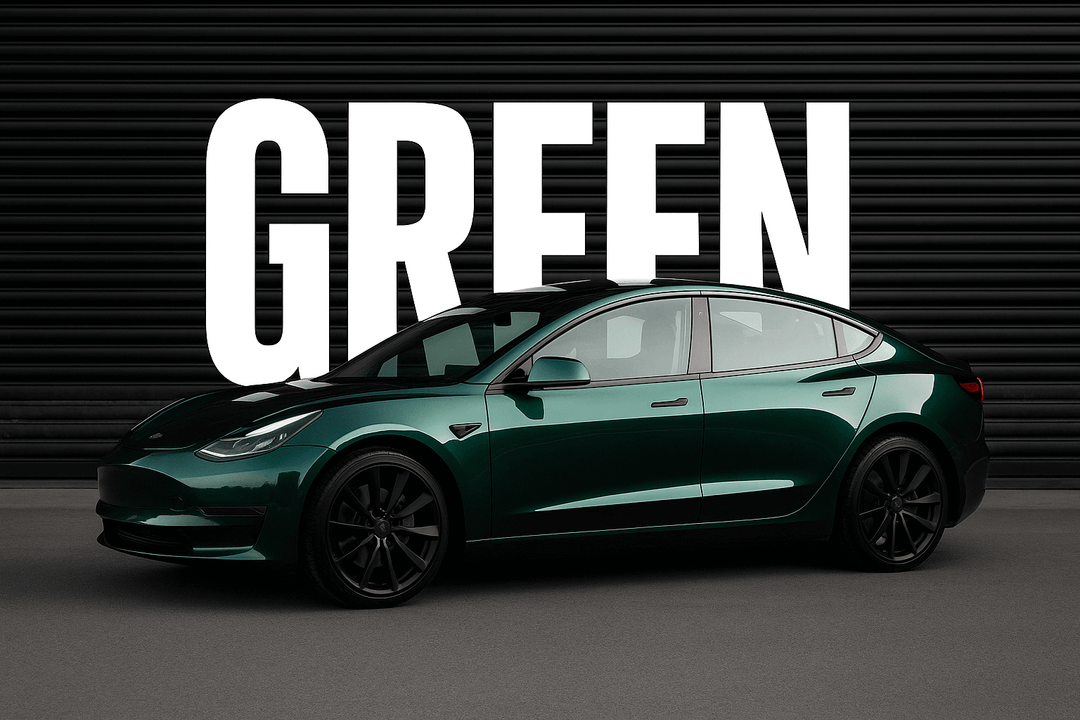

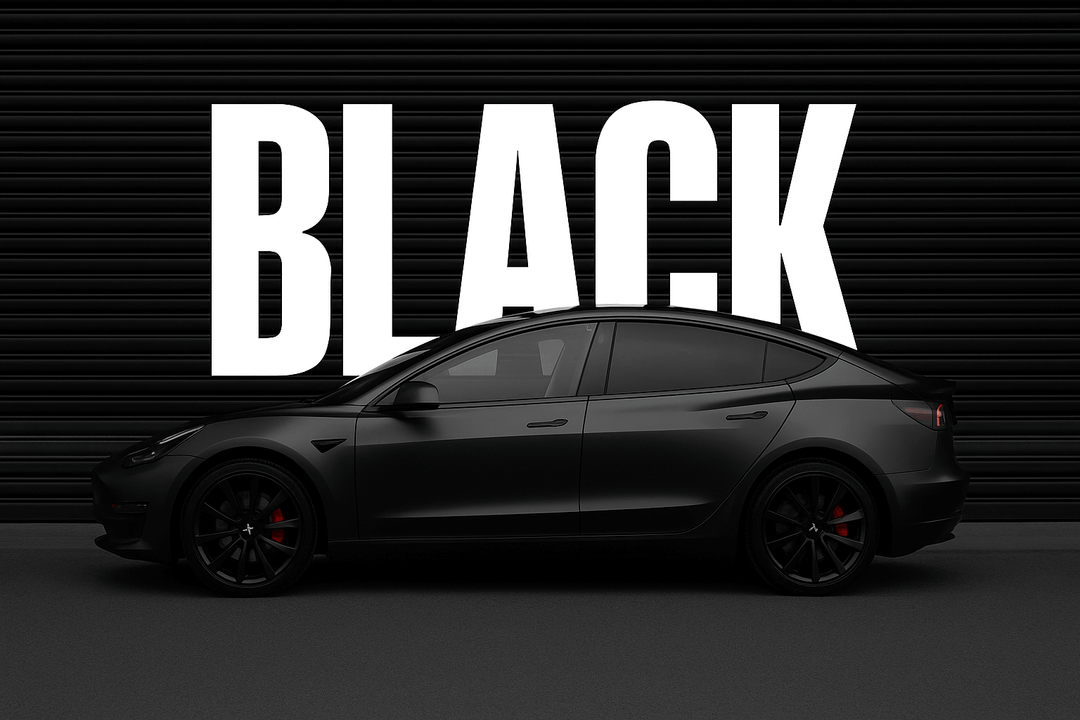

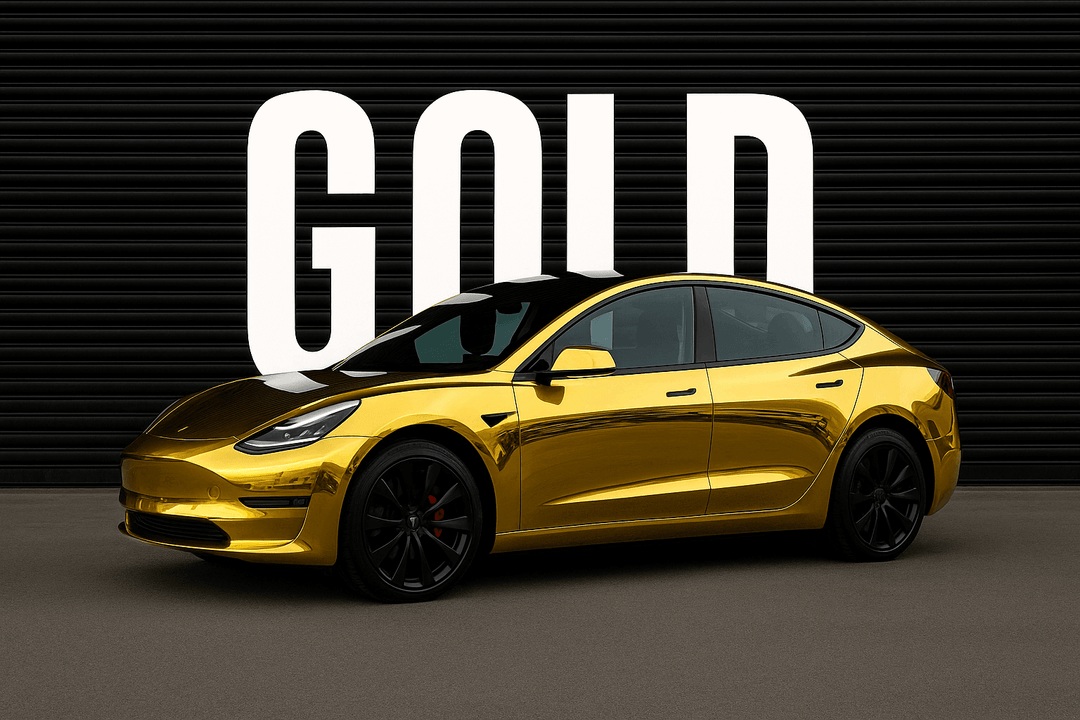

Vinyl wraps are far more affordable than a full paint job, especially for a vehicle as large and unique as the Cybertruck. They come in an enormous range of colors and finishes, including gloss, matte, satin, metallic, chrome, and color-shifting effects. One of their biggest advantages is reversibility. When removed properly, the wrap leaves the original surface intact.

Cons of Vinyl Wraps

Compared to paint protection film, vinyl wraps have a shorter lifespan. They offer limited resistance to rock chips and heavy impacts, and the surface can scratch more easily. While they are excellent for visual customization, they are less focused on long-term protection.

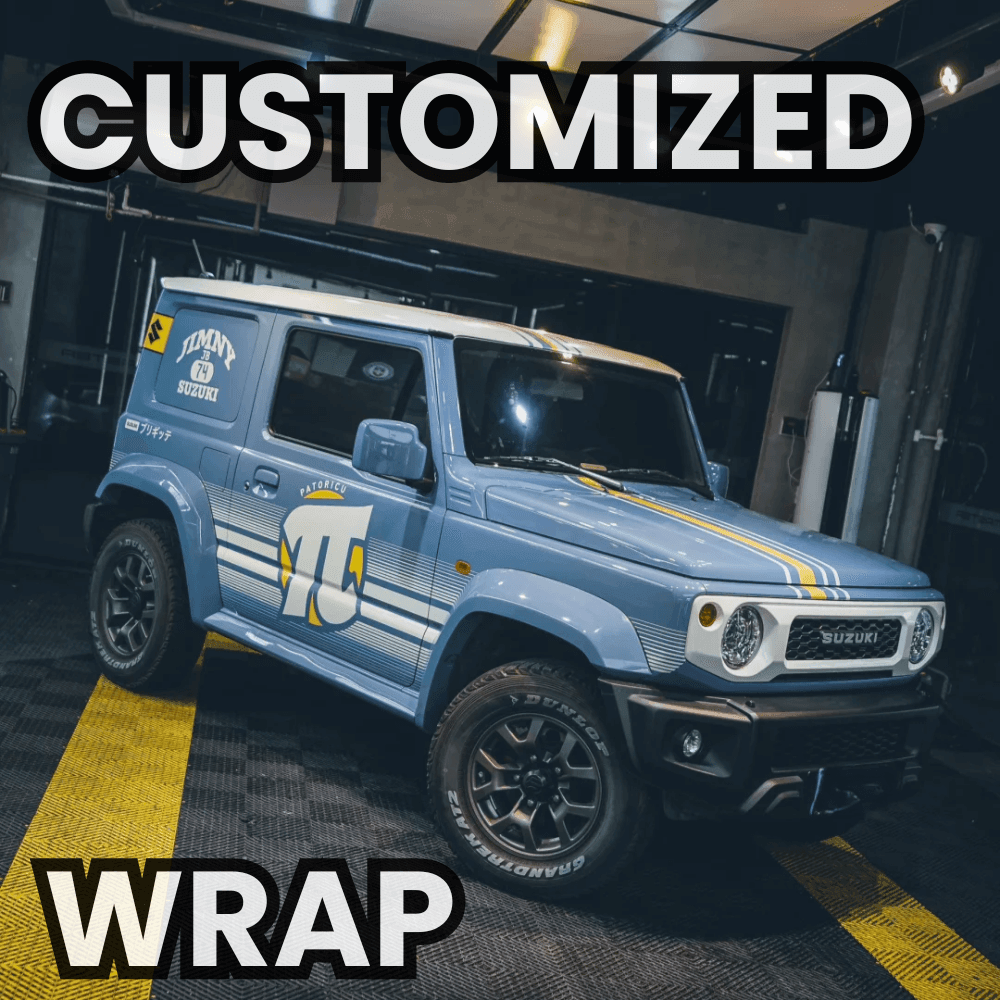

Vinyl wraps are a popular choice for Cybertruck owners who want creative freedom, lower cost, and the ability to change styles whenever they choose.

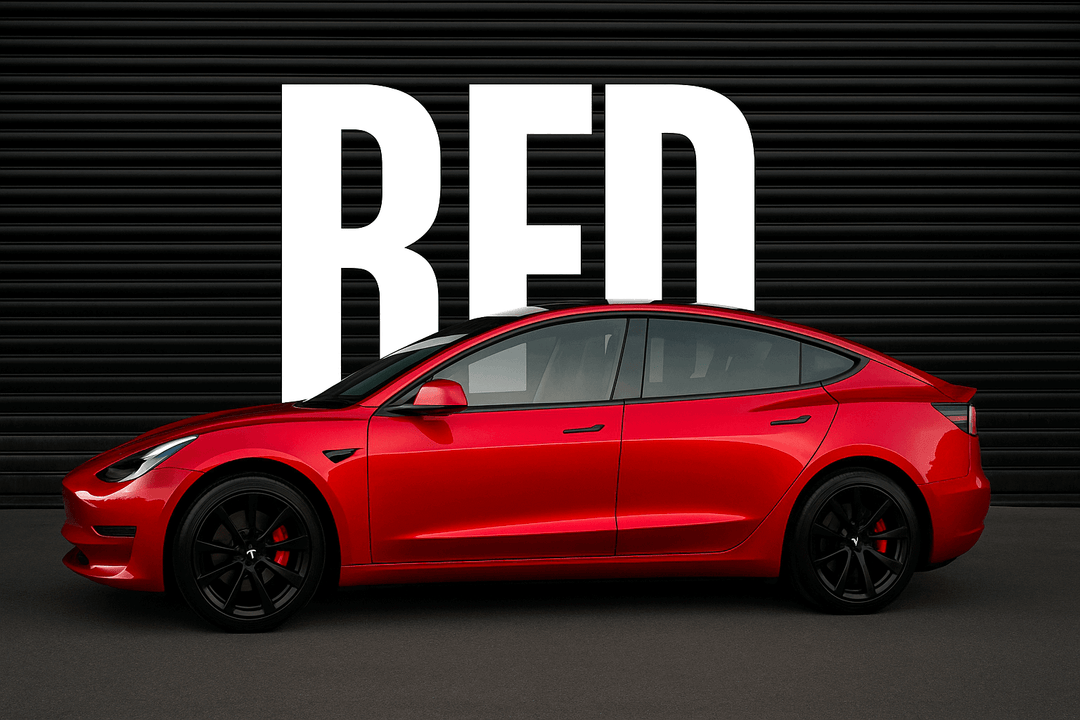

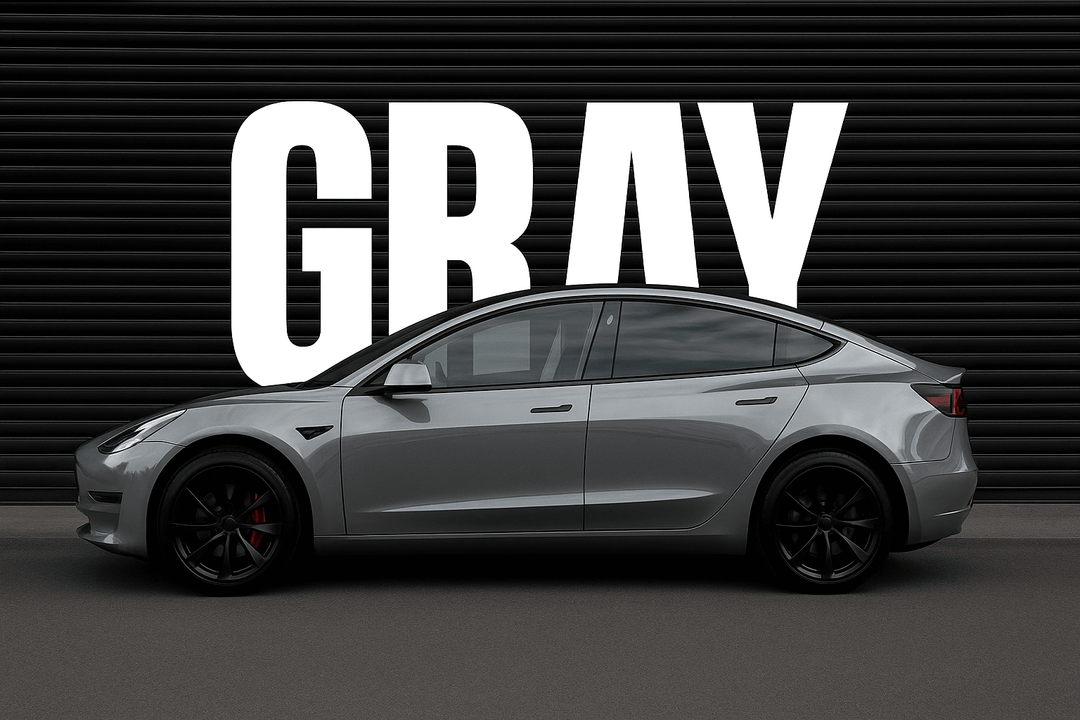

2. Color-Change Paint Protection Film (PPF)

What Is Color PPF?

Color-change paint protection film is a thick, TPU-based film that adds color while providing a high level of surface protection. Unlike traditional PPF, which is usually clear, color PPF has pigment built directly into the film. This allows it to change the appearance of the vehicle while still functioning as a protective barrier.

Why Color PPF Is Ideal for the Cybertruck

Color PPF works exceptionally well on the Cybertruck because it does not require sanding, etching, or any permanent modification to the stainless steel exoskeleton. The film adheres smoothly to the surface while preserving the steel’s natural corrosion resistance.

In addition to visual customization, color PPF offers strong protection against rock chips, scratches, road debris, and UV exposure. Yeswrap’s color PPF films feature self-healing properties, allowing light surface marks to disappear with heat. For Cybertruck owners who want both long-term durability and a refined, paint-like finish, color-change PPF is often the most balanced and premium alternative to traditional paint.

Vinyl Wrap vs Color PPF for Cybertruck

When choosing an alternative to painting a Cybertruck, vinyl wraps and color-change PPF are the two most common options. While both allow you to change the vehicle’s appearance without permanent modification, they differ significantly in performance, durability, and long-term value.

Durability Comparison

The biggest difference between vinyl wrap and color PPF is thickness. Vinyl wrap is a thinner film designed primarily for visual change. Color PPF is much thicker and built for protection first. This added thickness gives color PPF stronger resistance to rock chips, road debris, and daily wear. Vinyl wraps can handle normal use, but they are more vulnerable to impact damage over time.

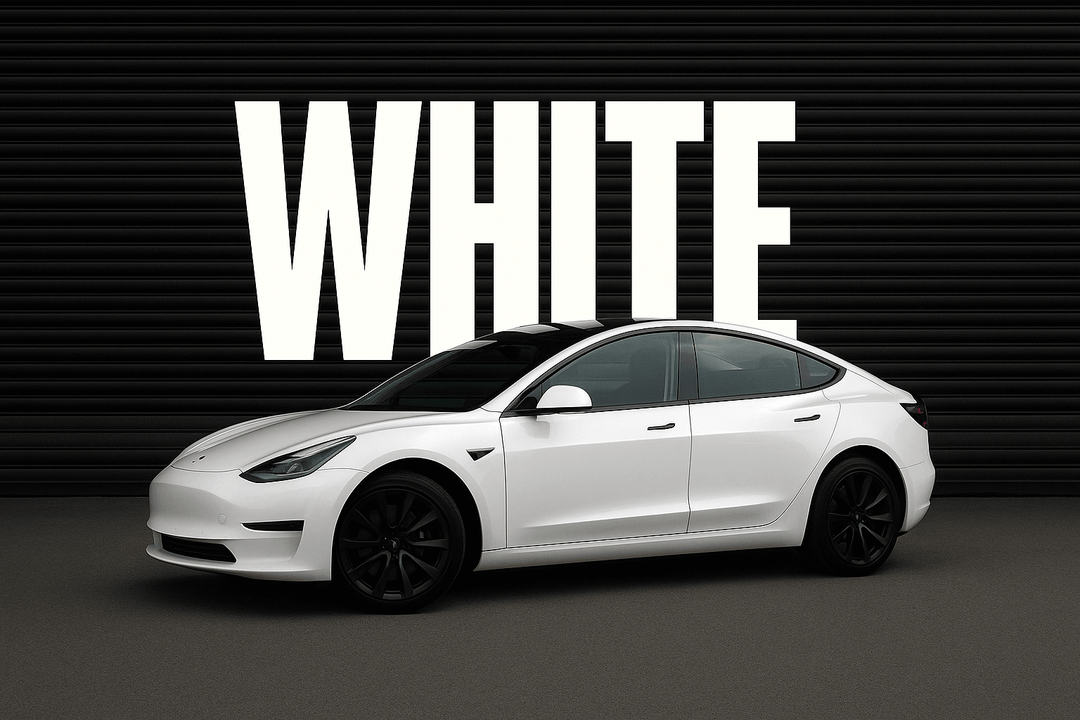

Appearance and Finish Quality

Color PPF delivers a more paint-like appearance, with smoother reflections and a refined surface. The thickness of the film adds visual depth, making colors appear richer and more consistent across large panels. Vinyl wraps still offer excellent variety and creativity, but they generally lack the same depth and surface uniformity found in color PPF.

Longevity

Vinyl wraps typically last between three and five years, depending on climate, care, and driving conditions. Color-change PPF is designed for longer service life and often lasts seven to ten years with proper maintenance. For Cybertruck owners planning to keep their vehicle long-term, this difference is significant.

Cost Comparison

Vinyl wraps have a lower upfront cost, both in material and installation, making them attractive for budget-conscious customization or short-term style changes. Color PPF costs more due to the premium TPU material and more complex installation process. However, when long-term durability, protection, and reduced need for replacement are considered, color PPF often provides better overall value for the Cybertruck.

Is PPF Better Than Vinyl for the Cybertruck?

Whether PPF is better than vinyl for a Cybertruck depends on how the vehicle is used and what the owner values most. Both options have clear advantages, but they serve different priorities.

When PPF Is the Better Choice

PPF is ideal for Cybertruck owners who want maximum protection along with a color change. Its thicker TPU construction offers strong resistance to rock chips, scratches, and environmental damage. Self-healing properties help maintain a clean surface over time, making PPF well suited for daily driving, highway use, or off-road conditions. It is also a better option for long-term ownership, as it preserves the stainless steel underneath and maintains a paint-like finish for many years.

When Vinyl Still Makes Sense

Vinyl wraps remain a practical choice for owners focused mainly on appearance and flexibility. They offer a wider range of creative designs, including complex graphics, camo patterns, and bold color shifts, often at a lower cost. Vinyl is also easier to replace, making it a good option for short-term styling, seasonal changes, or promotional vehicles.

So, if your priority is durability, protection, and long-term value, color PPF is the stronger choice for the Cybertruck. If you want creative freedom, lower upfront cost, and the ability to change designs more frequently, vinyl wrap may be the better fit. Both options outperform traditional paint on the Cybertruck, offering safer and more practical ways to customize its distinctive stainless steel body.

How Much Does Color PPF Cost for a Cybertruck?

The cost of color-change paint protection film for a Tesla Cybertruck varies based on materials, coverage, and installation. For a full Cybertruck color PPF installation, total costs typically range from the mid to high four figures when professionally installed. Material cost is a major part of this. But, a 5 ft × 69 ft roll of color PPF from Yeswrap costs less than $1,500, making it a competitive option compared to many premium films on the market. Installation labor can vary widely depending on location and complexity.

How Long Does PPF Last on a Tesla Cybertruck?

Paint protection film is designed for long-term durability. Yeswrap's high-quality PPF typically lasts between seven and ten years. Color-change PPF follows a similar lifespan, provided it is cared for correctly. The film is engineered to resist UV exposure, minor impacts, and surface wear while maintaining color stability and clarity over time.

Environmental and Usage Factors

The lifespan of PPF can vary depending on driving conditions and environment. Frequent highway driving, off-road use, and exposure to harsh weather can increase wear. Strong sunlight, extreme temperatures, road salt, and chemical contaminants may also affect longevity. Cybertrucks used in demanding conditions may see faster aging, while vehicles driven moderately and stored indoors often retain PPF longer.

Maintenance Tips That Extend Lifespan

Regular hand washing with mild, pH-neutral soap helps prevent buildup that can degrade the film. Avoid automatic car washes with abrasive brushes. Promptly remove bird droppings, tree sap, and bugs to prevent staining. Parking in shaded areas or using a car cover can further reduce UV exposure. Periodic inspection allows small issues to be addressed early, helping the PPF last as long as possible.

Final Thoughts: Should You Paint a Cybertruck?

Painting a Tesla Cybertruck using traditional automotive methods is rarely a practical choice. The ultra-hard stainless steel exoskeleton that defines the truck’s strength and durability also makes paint adhesion difficult, costly, and prone to long-term issues. Sanding required for paint prep can compromise the steel’s protective layer, and even a professionally applied paint job may chip or fail sooner than expected.

For most owners, the better solution is to choose a surface film that preserves the underlying material while delivering the look you want. Vinyl wraps offer wide creative freedom and a lower cost upfront, making them ideal for bold graphics, seasonal designs, or frequent changes. Color-change paint protection film (PPF) adds thickness, durability, and protection against chips, scratches, and UV exposure—all while delivering a refined, paint-like finish.

Both options outperform traditional paint on the Cybertruck and keep customization reversible. Whether you’re enhancing style, protecting the surface, or turning your truck into a branding platform, there’s a wrap solution that fits.

Ready to customize your Cybertruck? Explore and order vinyl wraps or color PPF at Yeswrap to get the look you want without compromising the integrity of the vehicle.

Related Articles: