How to Prevent Your Car Wrap from Peeling

What Causes Vinyl Wraps to Peel?

A vinyl wrap is a great way to enhance your vehicle’s aesthetics, but due to installation errors, environmental factors, or vehicle damage, may cause peeling.

1. Poor Surface Preparation

One of the most common reasons for peeling vinyl wraps is improper surface preparation. Before applying a wrap, the car’s surface must be thoroughly cleaned and degreased to ensure strong adhesion.

Dirt, grease, or wax residue weakens the adhesive, causing the vinyl to lift over time.

Scratches, dents, or rust can create uneven surfaces, leading to bubbling and peeling.

If a wrap is applied over contaminants or damage, it won’t bond properly and may start peeling within weeks.

2. Low-Quality Vinyl Wrap Material

Not all vinyl wraps are created equal. Cheaper wraps tend to be made with low-grade adhesives and thin materials that don’t last as long.

Budget-friendly wraps may shrink or crack under extreme weather conditions.

Inferior adhesives lose their grip, leading to premature peeling.

3. Improper Installation Techniques

Even high-quality vinyl can start peeling if not installed correctly. Common mistakes include:

Not stretching the wrap evenly, causes tension that leads to lifting at edges.

Trapped air bubbles, which weaken the adhesive bond.

Failing to use a heat gun properly to seal edges and curves.

Rushing the installation process leads to weak adhesion points.

To prevent these issues, professional installation is highly recommended.

4. Exposure to Harsh Elements

Environmental conditions play a major role in how long your vinyl wrap lasts. Continuous exposure to UV rays, rain, and extreme temperatures can degrade both the vinyl and adhesive.

Sunlight exposure causes wraps to fade and dry out, leading to cracks.

Heavy rain and moisture can weaken adhesion, especially if water seeps under the wrap.

Extreme heat or cold can cause vinyl to expand and contract, leading to lifting at edges.

Frequent exposure to road salt (in snowy regions) can deteriorate the adhesive faster.

5. Frequent Pressure Washing

Using a pressure washer incorrectly can quickly damage a vinyl wrap. High-pressure water forces moisture under the edges, causing them to lift and peel.

If the pressure is too strong (over 2000 PSI), it can weaken the adhesive.

Holding the nozzle too close to the wrap can tear or lift the vinyl.

Using harsh detergents or stiff brushes can erode the protective coating.

To prevent peeling, hand washing with mild soap and a microfiber cloth is the safest cleaning method.

6. Physical Damage & Everyday Wear

While vinyl wraps are durable, they are not invincible. Various external factors can lead to peeling:

Stone chips and road debris can cause small tears that expand over time.

Scratches from gas pumps or electric chargers can damage the wrap’s edges.

Parking lot accidents or door dings can lift sections of the wrap.

How to Prevent Your Car Wrap from Peeling

1. Hire a Professional to Install Your Wrap

Many peeling issues arise from poor surface preparation and improper techniques.

✔ Ensure the car is thoroughly cleaned and degreased before installation to prevent dirt from interfering with adhesion.

✔ Hire a professional installer to avoid bubbles, wrinkles, and weak adhesion points.

✔ Avoid installing vinyl in extreme temperatures, as heat causes overstretching and cold can make the wrap brittle.

2. Regular Cleaning & Maintenance

Routine cleaning helps preserve the adhesive bond and prevents contaminants from degrading the vinyl.

✔ Hand wash your car wrap using mild soap and lukewarm water at least once a week.

✔ Use microfiber cloths instead of rough sponges to prevent scratches.

✔ Avoid high-pressure washing, especially near the edges, as strong water jets can lift the vinyl.

✔ Use a vinyl-safe cleaning solution and avoid harsh detergents or solvents that can weaken the adhesive.

3. Protecting Your Wrap from Weather Damage

Exposure to harsh weather conditions can accelerate peeling and fading.

✔ Park in shaded areas or use a car cover to reduce sun exposure and prevent UV damage.

✔ Apply a UV-protection spray to minimize fading, cracking, and premature wear.

✔ Dry your wrap immediately after rain or snow to prevent water damage and lifting at the edges.

4. Avoid Scratches & Physical Damage

Physical damage can create weak points that lead to peeling over time.

✔ Be cautious with door edges and sharp objects that might scratch the wrap.

✔ Avoid automatic car washes that use stiff brushes, as they can lift the edges and degrade the wrap.

✔ Watch out for gas pumps and electric chargers, as frequent contact can cause minor damage near access points.

When and How You Can Repair Vinyl Wrap

While minor issues can often be repaired, some damage may require a full wrap replacement. Here’s how to determine when to repair, when not to repair, and how to fix common vinyl wrap problems.

When to Repair Vinyl Wrap

Not all vinyl wrap damage means you need a full replacement. Some issues can be fixed with simple techniques if caught early.

✔ Small Scratches and Scuffs – If the damage is just on the surface and hasn’t penetrated the vinyl, it can often be repaired.

✔ Peeling Edges or Corners – If small sections of the wrap are lifting, they can be re-adhered if the underlying surface is clean.

✔ Fading or Discoloration – In some cases, fading can be reversed by removing contaminants or applying a vinyl rejuvenator.

✔ Air Bubbles – Small trapped air pockets can be carefully removed with the right technique.

When Not to Repair Vinyl Wrap

In some cases, a repair might not be practical or effective, and a replacement is the better option.

✖ Deep Cuts or Tears – If the vinyl has been torn completely through, attempting a repair may not hold up well and could be noticeable.

✖ Large Areas of Damage – If more than one section of your wrap is peeling, bubbled, or damaged, replacing the affected panel is usually more effective.

✖ Old or Brittle Vinyl – Vinyl wraps that have been exposed to the elements for years lose their flexibility, making them difficult to repair.

How to Repair Vinyl Wrap

1. Fixing Scratches and Scuffs

✔ Step 1: Clean the area with a vinyl-safe cleaner to remove dirt and debris.

✔ Step 2: Use a heat gun to gently warm the vinyl—this can help the material regain its original shape.

✔ Step 3: Apply a vinyl wrap conditioner or polish to restore the finish.

✔ Step 4: If scratches remain, consider using a vinyl-safe sealant to improve the appearance.

💡 Tip: Avoid excessive heat, as overheating can warp or melt the wrap.

2. Repairing Peeling Edges or Corners

✔ Step 1: Clean the affected area with isopropyl alcohol to remove contaminants.

✔ Step 2: Carefully lift the peeling edge and clean underneath with a 50/50 water and alcohol mix. Let it dry completely.

✔ Step 3: Apply an adhesive primer to improve bonding, then press the vinyl back into place.

✔ Step 4: Use a heat gun and a squeegee to secure the edge and ensure a firm seal.

💡 Tip: If peeling continues, consider using a high-quality vinyl adhesive designed for wrap repairs. Edge-sealing adhesives should only be used as a last resort before replacing the panel.

3. Removing Air Bubbles

✔ Step 1: Use a fine needle to puncture the air bubble at the center.

✔ Step 2: Press gently from the edges toward the hole to push the air out.

✔ Step 3: Apply heat with a heat gun to soften the vinyl and smooth it out with a squeegee.

💡 Tip: Never use a razor blade or knife to pop bubbles—it can cause permanent tears in the wrap.

4. Restoring Fading or Discoloration

✔ Step 1: Thoroughly clean the wrap with a vinyl-safe cleaner to remove any surface contaminants.

✔ Step 2: Rub out minor discoloration using a microfiber cloth and a vinyl-safe polish (only for glossy wraps).

✔ Step 3: Apply a polymer-based vinyl sealant to rejuvenate the color and add UV protection.

✔ Step 4: For glossy wraps, use a polishing technique—but ensure the surface is well-lubricated to prevent heat buildup.

💡 Tip: If the vinyl is heavily faded or damaged from UV exposure, a panel replacement is usually the best solution.

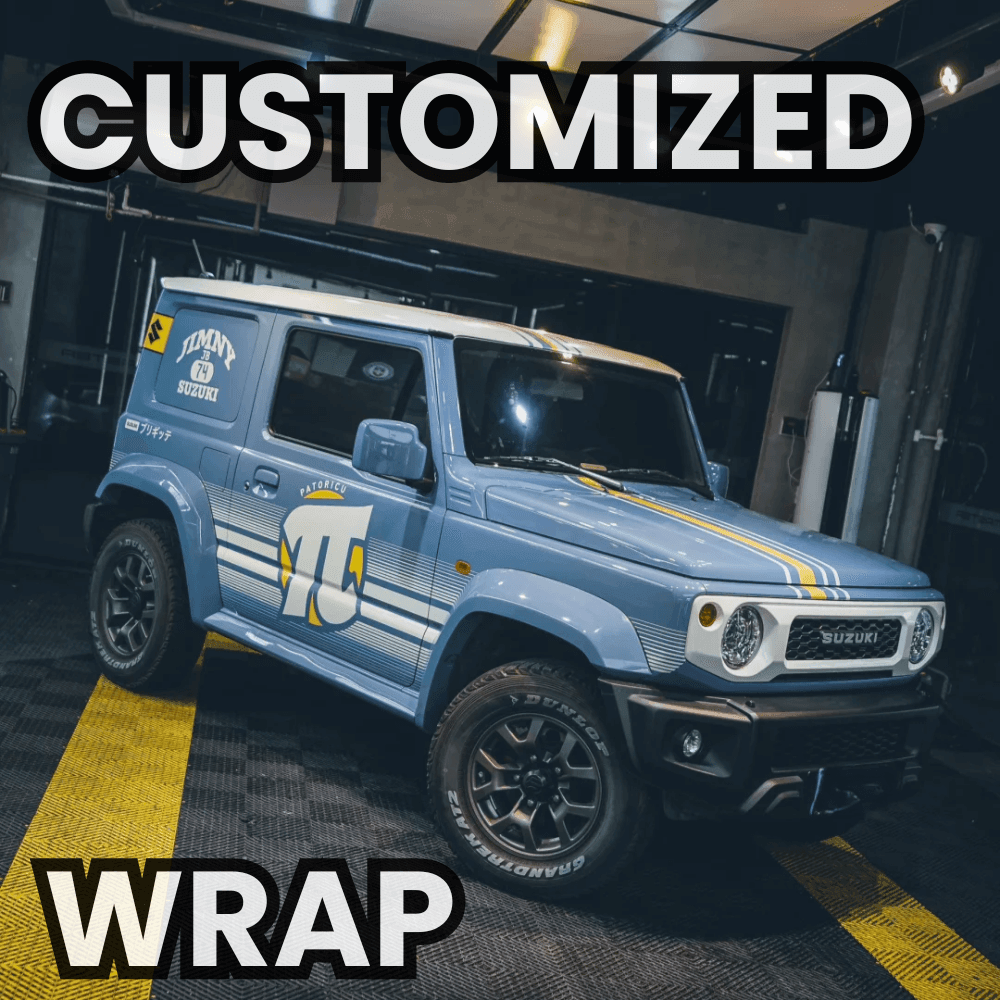

Get the Best Vinyl Wraps & Professional Installation

A high-quality vinyl wrap not only transforms the look of your vehicle but also provides long-lasting protection—when done right. Don't settle for low-quality materials or improper installation that leads to peeling and premature wear.

At Yeswrap, we offer premium vinyl wraps designed for durability, style, and superior adhesion. Whether you need a full vehicle wrap, partial wrap, or custom design, our professional installation ensures a flawless, long-lasting finish.

✅ Top-tier vinyl wraps with vibrant colors and finishes

✅ Expert installation to prevent bubbles, peeling, and weak adhesion

✅ Comprehensive maintenance tips to keep your wrap looking fresh

Upgrade your ride with Yeswrap today! Contact us through our online form and let’s discuss how we can provide the perfect vinyl wrap solution for your vehicle. Your car deserves the best—choose Yeswrap!

Browse for more vinyl wrap finish > Gloss Vinyl Wrap | Matte Vinyl Wrap | Metallic Vinyl Wrap | Chrome Vinyl Wrap

View for more color vinyl wrap > Purple Vinyl Wrap | Pink Vinyl Wrap | White Vinyl Wrap | Black Vinyl Wrap | Green Vinyl Wrap | Gold Vinyl Wrap | Gray Vinyl Wrap | Silver Vinyl Wrap | Yellow Vinyl Wrap

Also check out our special effect vinyl wrap > Custom Car Wrap | Gradient Vinyl Wrap | Rust Vinyl Wrap | Iridescent Vinyl Wrap | Carbon Fiber Vinyl Wrap | Camouflage Vinyl Wrap