Can You Vinyl Wrap Your Rusty Car?

Many car owners explore vinyl wrapping to enhance their vehicle's appearance, protect its paint, or showcase a unique style. However, wrapping a car isn’t as straightforward when rust enters the picture. Rust can compromise the surface integrity, raising questions about whether a wrap is even possible—or worth the effort.

If your vehicle has visible rust spots or extensive damage, you might be tempted to mask the imperfections with a stylish vinyl wrap. But is that a practical solution? In this guide, we’ll dive into the challenges of wrapping a rusty car, how to prepare the surface for success, and whether it’s the right choice for you.

Can Vinyl Wrap Be Applied To A Rusted Car?

The answer is simple: No, vinyl wrap adheres best to smooth, clean paintwork, applying vinyl wrap directly onto rust is not recommended. Rust compromises the integrity of your vehicle’s surface, and wrapping over it can trap moisture, accelerating the corrosion process. If the paint beneath is peeling, bubbling, or flaking due to rust, the wrap won’t stick properly or may peel off prematurely.

The only viable approach to wrapping a rusted car is to address the rust first. This involves removing the rust entirely, repairing the surface, and applying a primer to create a stable, smooth base for the vinyl wrap to adhere to. Without this preparation, a successful, long-lasting wrap simply isn’t possible.

The Challenges Of Wrapping A Rusty Car

Rust presents a significant challenge when applying vinyl wraps. It damages a vehicle's surface and creates an unstable foundation for adhesion, impacting both the wrap's appearance and longevity.

How Rust Affects the Vehicle’s Surface

Rust occurs when the metal on a vehicle reacts with moisture and oxygen, leading to corrosion. This process eats away at the metal, creating rough, uneven patches that compromise the smoothness of the surface. In severe cases, rust can cause holes, leaving the surface fragile. These imperfections make it difficult for vinyl to adhere uniformly, which is essential for a seamless wrap.

Why Rust Hinders Vinyl Wrap Adhesion

Vinyl wraps rely on a smooth, clean, and stable surface for proper application. Rust disrupts this process in several ways:

- Weak Adhesion: The wrap’s adhesive bonds best to painted surfaces. When rust has damaged or caused paint to flake, the adhesive loses its grip.

- Moisture Entrapment: Wrapping over rust can trap moisture underneath, allowing the rust to spread beneath the vinyl. This shortens the wrap's life and can worsen the vehicle’s condition over time.

- Irregular Application: The uneven texture of rust prevents the wrap from laying flat, leading to bubbles, wrinkles, and peeling.

Durability and Aesthetic Issues

Even if a wrap is applied to a rusted car, it’s unlikely to last long. The rust underneath will continue to erode the surface, causing the wrap to detach in sections. Additionally, the unsightly bumps and imperfections of rust will remain visible, defeating the purpose of using a vinyl wrap for a sleek, polished look. Over time, these flaws will only become more pronounced as the rust progresses.

How To Prepare Rusty Car Before Vinyl Wrapping

Proper preparation is essential before wrapping a rusty car to ensure the vinyl adheres securely and lasts as long as possible. Skipping these steps will lead to poor results and potential damage to both the wrap and the car.

Cleaning and Removing Rust

The first step in preparing a rusty car is thoroughly cleaning and eliminating all rust from the surface. Here’s how to do it:

- Wash the Car Thoroughly: Use a car-safe detergent to remove dirt, grime, and grease from the vehicle’s surface. Pay special attention to the rusted areas to ensure no loose debris remains.

- Sand the Rust Away: Using sandpaper or a sanding tool, remove the rust down to the bare metal. Start with coarse sandpaper to remove larger rust patches and finish with finer grit to smooth the surface. This step is critical to create a clean, rust-free area for the wrap.

- Apply a Rust Converter (Optional): If some rust spots cannot be completely removed, use a rust converter. This product chemically transforms rust into a stable compound, reducing the risk of further corrosion.

Treating and Priming the Surface for Better Adhesion

Once the rust is removed, the surface must be treated and primed to ensure the vinyl wrap adheres properly and lasts over time:

- Fill Holes or Dents: If rust has created holes or uneven areas, use body filler to restore a smooth surface. Follow the product instructions to sand and shape the filler until it matches the car’s contours.

- Apply a Rust Inhibitor: To prevent the rust from returning, coat the treated area with a rust inhibitor. This adds an extra layer of protection and increases the lifespan of the wrap.

- Prime the Surface: Use an automotive-grade primer on the treated area. A good primer not only seals the surface but also provides an ideal base for the vinyl wrap to adhere to. Ensure the primer is fully cured before moving to the next step.

- Smooth the Surface: Perform a final sanding to ensure the surface is smooth and even. Use fine-grit sandpaper for this step to achieve a professional finish.

Other Conditions Preventing the Perfect Vinyl Wrap

Rust isn’t the only condition that can ruin the perfect vinyl wrap. Seemingly minor issues can have a significant impact on the final result, leaving you with a less-than-polished look.

Dents and Dings

While vinyl can adhere to a surface with small dents, it’s not recommended to wrap a car before addressing these imperfections. Dents can distort the appearance of the wrap, creating shadows and highlights that make the damage even more noticeable. Additionally, the wrap may fail to adhere properly in the recessed areas, increasing the likelihood of peeling or bubbling over time.

To achieve a smooth, professional finish, repair all dents before applying the vinyl wrap. This ensures a flat surface that enhances the wrap’s sleek appearance.

Peeling Paint

Peeling or flaking paint poses a major obstacle to successful wrapping. Vinyl needs a solid, stable base for adhesion, and peeling paint is anything but. Attempting to apply a wrap over these areas will result in poor bonding, with the wrap lifting and peeling away along with the loose paint.

Before wrapping, remove any loose paint and touch up the affected areas with a primer or new paint to ensure the wrap has a reliable surface to stick to.

Heavy Scratches

Deep scratches may not seem like a big issue, but they can ruin the final look of your wrap. Vinyl tends to highlight surface imperfections, making scratches more visible once the wrap is applied. Worse, if you decide to remove the wrap later, the adhesive could further damage the paint around the scratched areas.

Repair scratches beforehand by sanding and refinishing the surface. This ensures a flawless finish and protects the paintwork during future wrap removal.

‘Orange Peel’ Texture

An uneven paint job with an ‘orange peel’ texture—a bumpy, dimpled surface—can disrupt the appearance of a vinyl wrap. The uneven surface amplifies the effect, making the wrap look distorted rather than smooth and polished.

If your car has this texture, it’s best to have the paint job corrected before wrapping. Consult with a professional to ensure the paint is smooth and fully cured before applying the vinyl.

Can Car Wrapping Prevent Rust?

A vinyl wrap applied to a rust-free car can offer some degree of protection against rust formation. The wrap acts as a barrier, shielding the paint from moisture, road salt, and other environmental factors that contribute to corrosion. This protective layer can help preserve the vehicle's surface, but only if the car’s paint and body are in pristine condition before the wrap is applied.

However, it’s important to note that a vinyl wrap cannot stop rust from spreading if it already exists. Any rust present on the car before wrapping will continue to develop beneath the vinyl, as the wrap does not eliminate moisture or repair damaged metal. For optimal results, the car's surface must be clean, smooth, and free from defects.

Additionally, while vinyl wrap protects the car’s exterior, it does not safeguard the undercarriage or internal components. Regular maintenance and inspections of these areas are essential to prevent rust from forming in hidden spots that a wrap cannot cover.

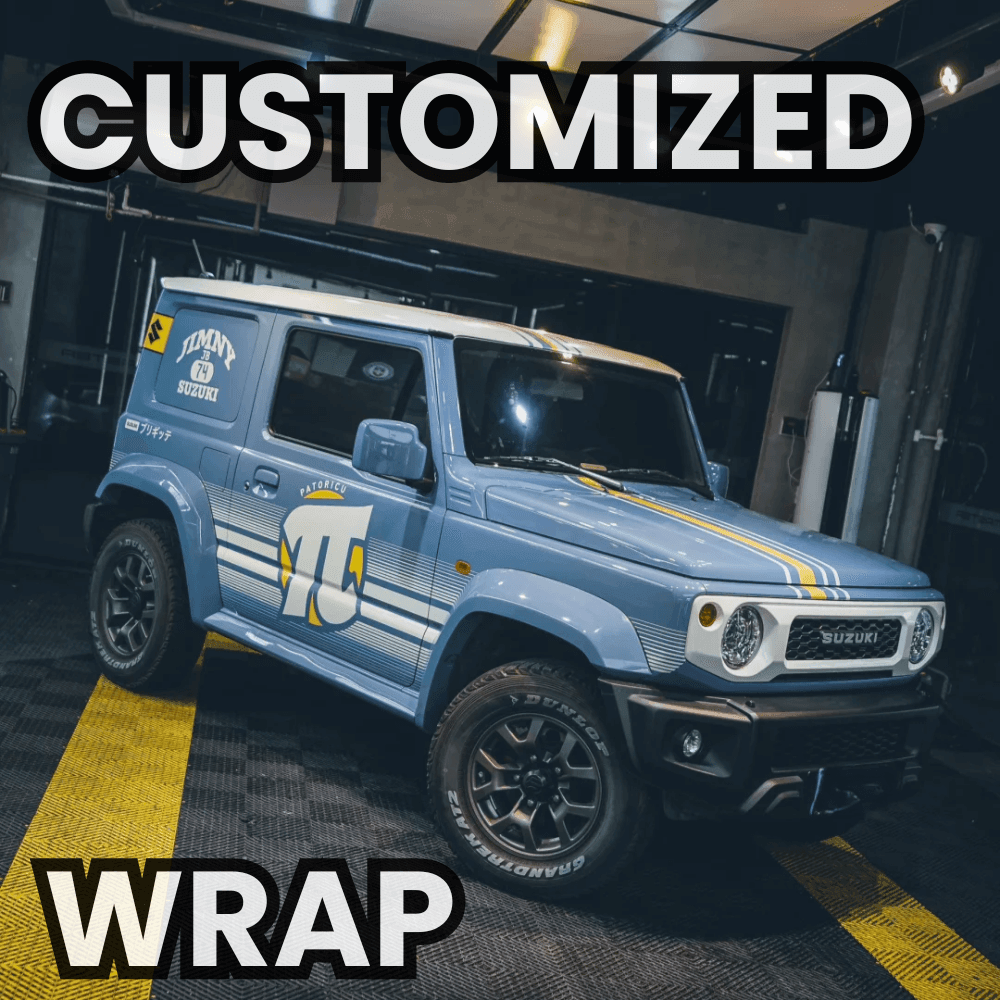

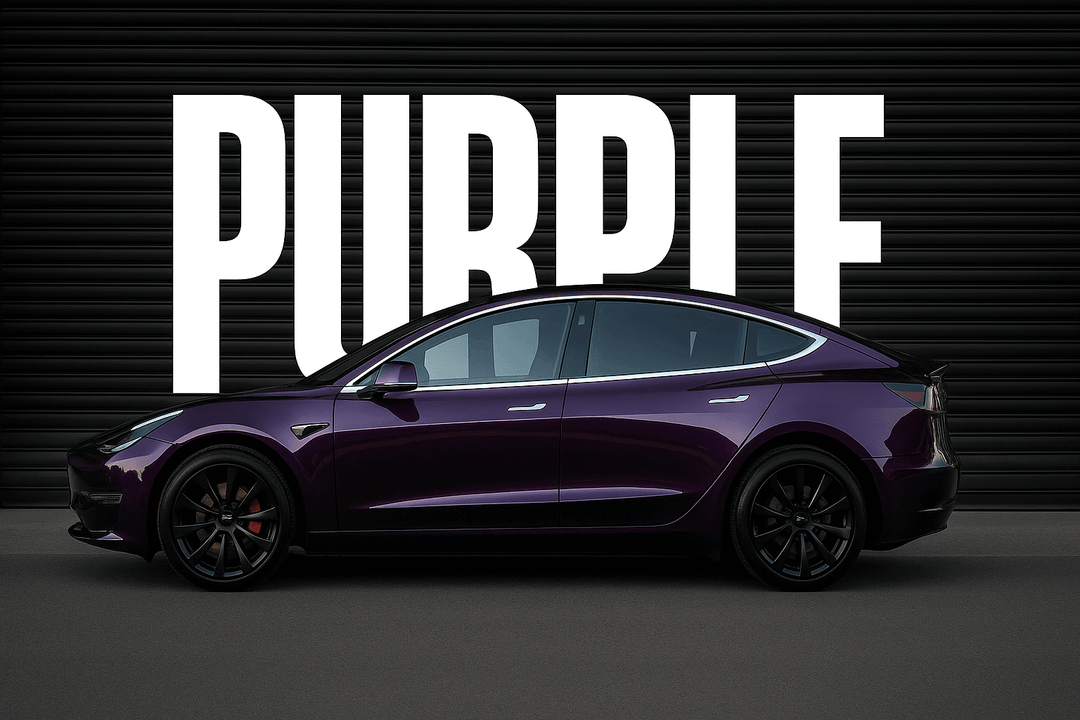

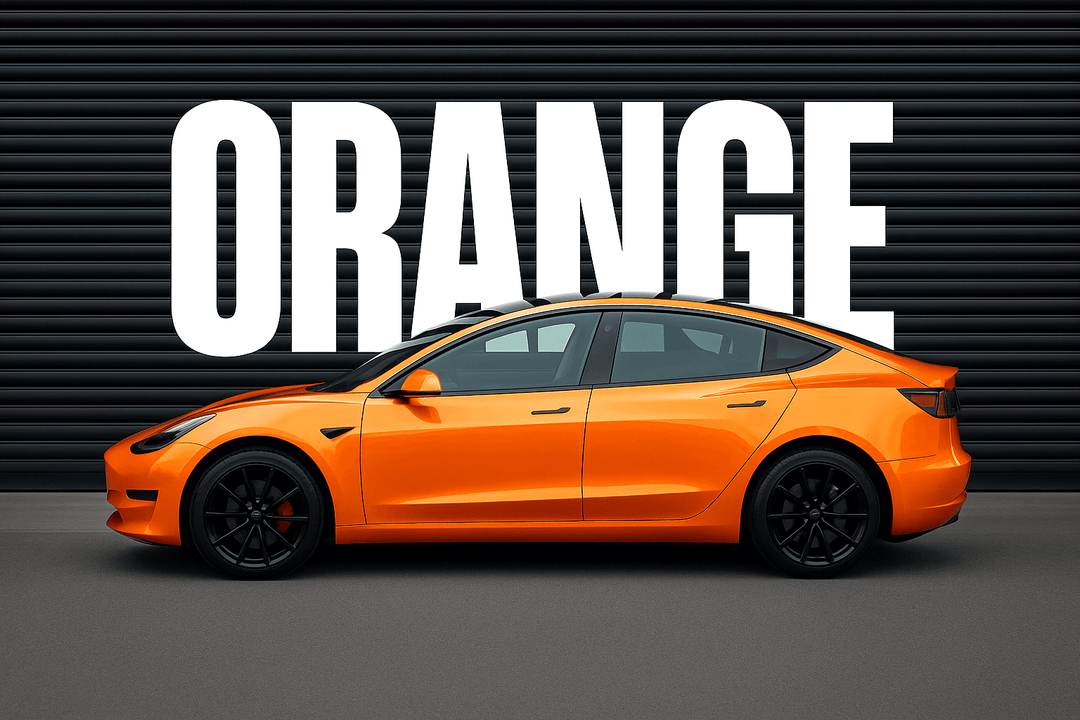

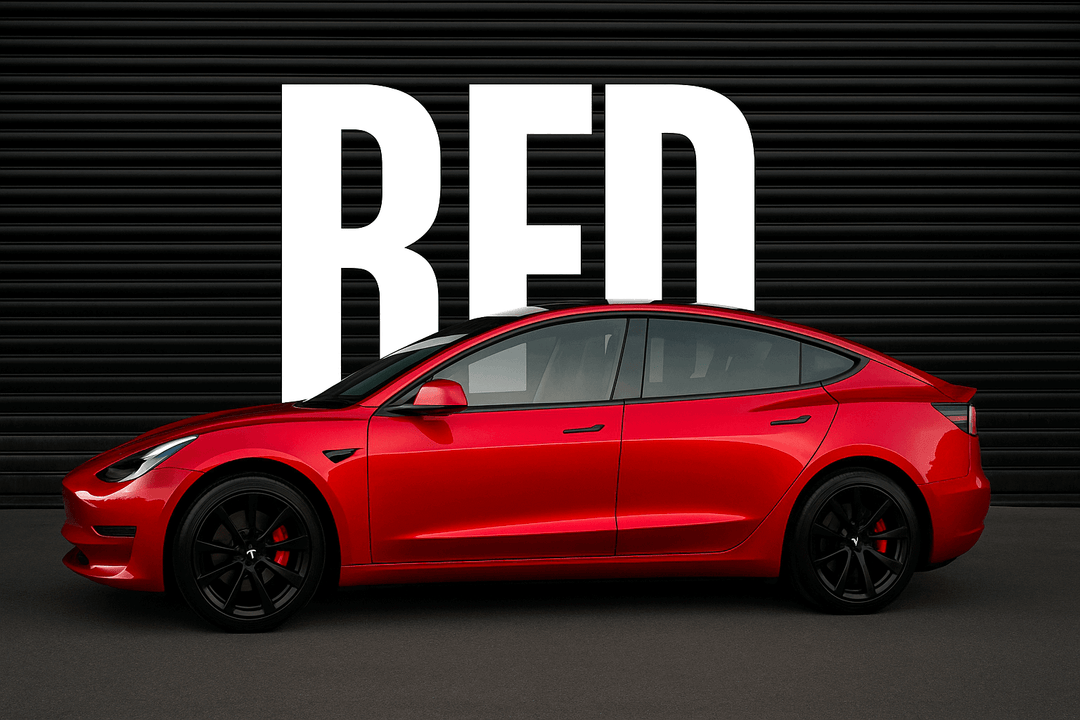

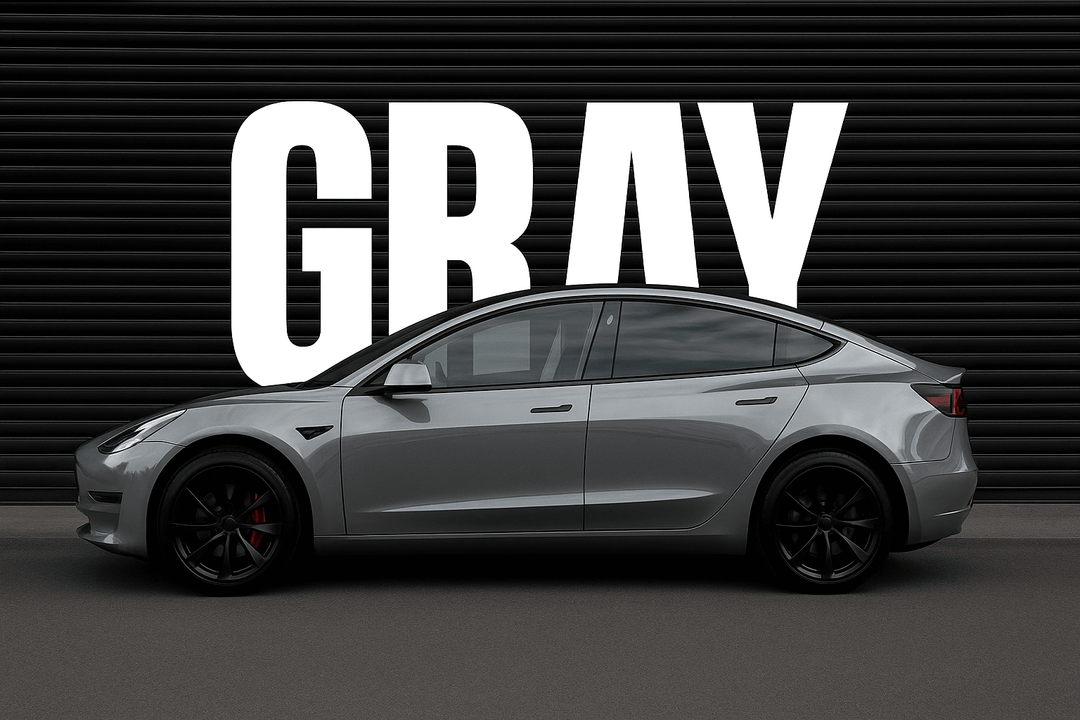

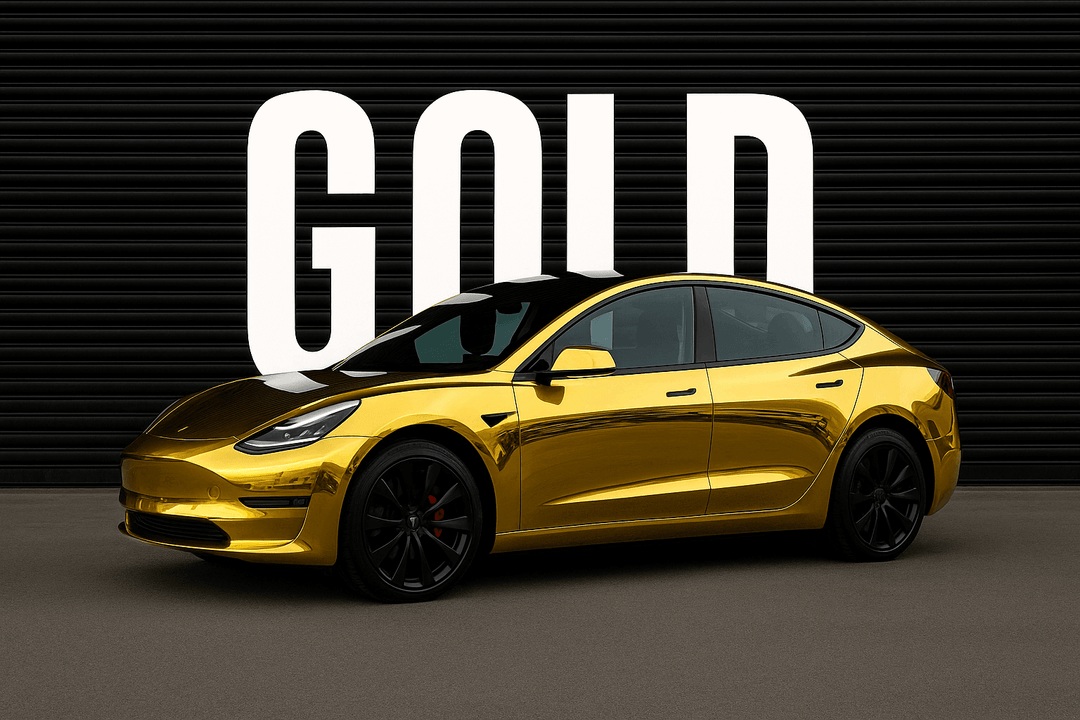

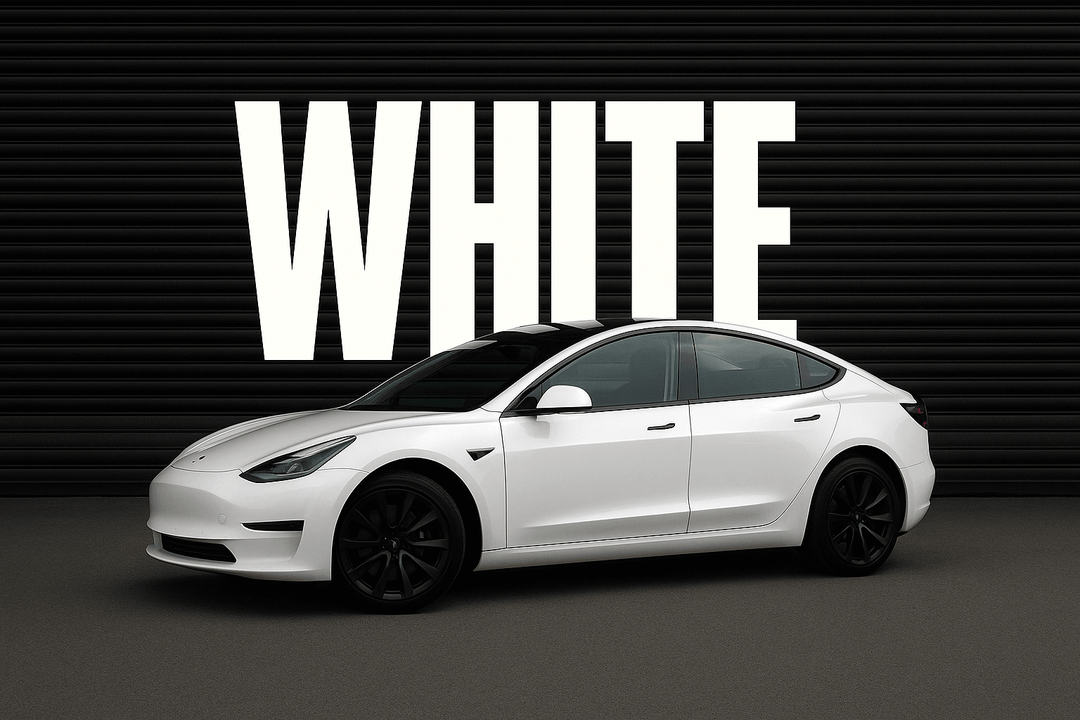

Yeswrap Makes Your Car Look Even Better

If your car is in great shape and you’re ready to elevate its appearance, Yeswrap has you covered with premium vinyl wraps that transform your vehicle. Whether you’re after a sleek new color, a bold design, or a unique finish, we specialize in creating a look that makes your car stand out.

At Yeswrap, we understand how much you care about your vehicle, and we’re here to help you turn heads on the road. Browse our high-quality vinyl wraps today to find out the best color vinyl for your car to get a stunning transformation!

Frequently Asked Questions

Can wrapping prevent further rusting?

While a vinyl wrap can provide some protection from external elements like rain, road salt, and UV rays, it will not stop existing rust from spreading. A wrap creates a barrier over the paintwork, but if rust is already present, it will continue to progress underneath the vinyl. For the best results, it’s essential to address rust before applying a wrap.

How much does it cost to prepare a rusty car for wrapping?

The cost to prepare a rusty car for wrapping can vary depending on the extent of the rust damage and the necessary repairs. Generally, the process includes rust removal, surface treatment, and priming, which could range from a few hundred to over a thousand dollars. If significant bodywork is needed, such as filling holes or repainting sections, the cost can increase. It’s best to consult a professional to get an accurate estimate based on your car’s condition.

How long will the wrap last on a rusty car?

A vinyl wrap applied to a rusty car may not last as long as one applied to a rust-free surface. The wrap’s durability depends on the extent of the rust and the preparation done before installation. If rust is not properly addressed, the wrap could peel, bubble, or lift much sooner.

On average, a well-maintained wrap can last 3-5 years, but this lifespan can be significantly reduced if applied to a car with untreated rust. To maximize the longevity of the wrap, it’s important to properly prep the car and maintain the wrap by cleaning it regularly and addressing any damage promptly.